Original URL: https://www.theregister.com/2014/06/12/geeks_guide_npl/

Measure for measure: We visit the most applied-physicist-rich building in the UK

Like an ass whose back with kilograms of Concorde bows...

Posted in Geek's Guide, 12th June 2014 09:01 GMT

Geek's Guide to Britain Shielded by lime trees in a quiet corner of south-west London, a low, modern building constructed of green glass sits on rolling lawns behind a high metal fence.

It’s a discreet facility save for a huge white sign facing the road with an blue official crest and three large letters that spell out NPL – the National Physical Laboratory.

The sign, the crest and high fence all suggest some sort of secret government research facility, camouflaged by obscurity amidst the leaves of London – the stuff of John Wyndham or Dr Who's Brigadier Alistair Gordon Lethbridge-Stewart.

This low-rise building comprises more than 380 laboratories and claims to be the UK's largest employer of applied physicists.

What this is, though, is one of the planet’s centres of excellence on testing and measuring. Testing and measuring what? Everything.

NPL is so good at testing and measuring, it has become the place to which government, industry and even other scientists turn to get things right. The result is that NPL has become embedded in history.

It was its test labs that determined a more precise value for g (acceleration due to gravity) in 1960 – calculated at 9.8118177 metres per second squared.

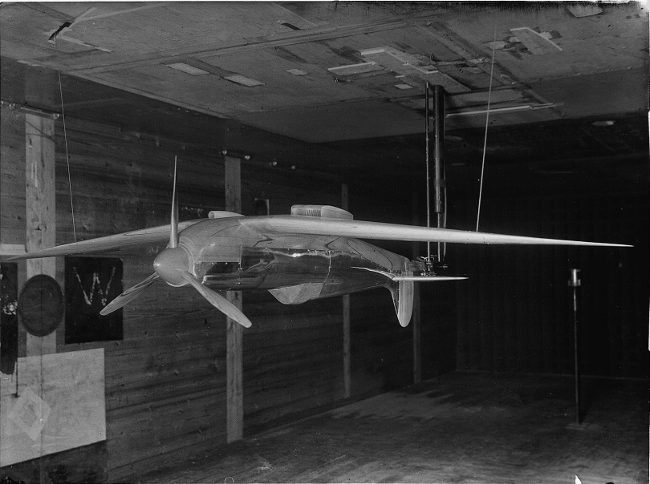

It was the body the UK Air Ministry turned to for critical tests on the Supermarine S.6 seaplane racer during the 1920s, helping it to win the coveted Schneider Trophy. Good thing, too: the design experience gained by Supermarine was later used in the manufacture of the famous Spitfire fighter, of which more than 20,000 were made. The Spitfire, along with the Hawker Hurricane, was crucial to Britain's ability to send Hitler’s Luftwaffe into a tailspin during the Second World War.

NPL: highly concentrated applied physicists, photo courtesy of NPL

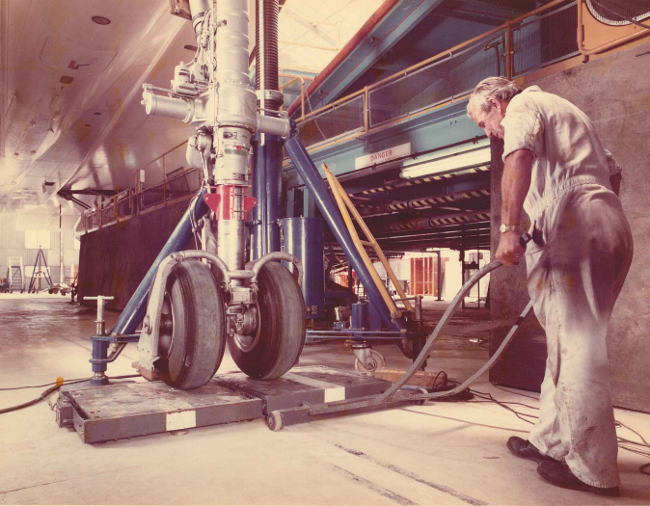

It was the experts at NPL who weighed a Concorde supersonic airliner in 1979, ensuring it conformed with the Civil Aviation Authority's rules. Scales calibrated by NPL were positioned beneath each of Concorde’s wheels to gauge the weight to within +/-3kg. The final weigh-in: 78,700kg. You can read more here (PDF).

NPL invents, too. Among its claims to fame: the first functioning atomic clock in 1955 and packet-switching in 1966 - a building block of the internet.

If all NPL had done, and does today, is weigh, test and measure, this would be a short story. But NPL has been and remains deeply involved in the units of measurement themselves - in making them more precise.

A more accurate second? Check. A reliable kilogram standard? That, too.

Seconds? Kilograms? Aren’t these supposed to be givens, writ in stone? We learned them in school and put them into practice every day without thinking.

Actually, they aren’t written in stone and NPL’s physicists have worked for decades towards ever more precise definitions. NPL gave us the atomic clock, but now it’s going further: working with laser-based time keeping to put an extra decimal point on the current definition of the second – defined as the rate at which caesium atoms flip when agitated by microwaves at a set frequency.

This obsession with the meticulous means NPL has become one of the world’s timekeepers. The mega-lab is jointly responsible for maintaining Universal Co-ordinated Time (UTC), the world's time standard since 1972 and the mechanism upon which all clocks and anything with a time piece in it relies.

UTC is a weighted average of International Atomic Time (TAI), which is the product of more than 200 atomic clocks in 50 labs worldwide - among them, NPL. So precise is NPL's atomic clock, though, that it's one of just six labs relied upon to keep an eye on the accuracy of UTC.

Forerunner of the Luftwaffe's curse, the Supermarine Spitfire, tested at NPL. Photo courtesy of NPL

If only there were some way to get a peek behind the scenes at this? There is - albeit rarely. NPL isn't top-secret and hush-hush and it does plenty of outreach to local schools, but for the general public you must wait for one of its rare open days, such as World Metrology Day on 20 May, when the masses got to wander the labs and probe NPL’s boffinery.

World Metrology Day commemorated the 1875 Metre Convention that established the metre and the kilogram as international standards – two of the units by which NPL lives and dies - and that saw these two units cast as physical objects – a metal bar and a solid cylinder both of platinum iridium.

The platinum iridium kilogram is still with us today – protected beneath two glass bell jars at the International Bureau of Weights and Measures (BIPM) just outside Paris. NPL is home to one of the working copies of that original, Number 18. The metal metre bar was replaced in 1960 by an atomic calculation based upon wavelengths.

I got a peek behind the lab doors ahead of World Metrology Day, with the manager of NPL outreach - Andrew Hanson.

Enter the Tardis

The buildings that housed most of that early work – such as the testing of the Spitfire – have gone as the work moved on to new fields. All that remains of that past is Bushy House, a country pile in Teddington, where NPL was first based in 1902, shortly after its creation in 1900 by the Royal Society.

What you tour today is the new building, completed in 2003. Inside it is like the Tardis: corridor upon corridor, room upon room. Some offices look more corporate than science – glass walls and office furniture – while others are exactly what you imagine when you think "laboratory": reinforced doors and spotless white rooms. Some labs, though are not at all what you'd imagine as places of science, as I’ll get to in a second. The number of doors sporting signs warning of radiation and lasers whip past so fast on the tour they become a blur.

The first set of labs we come to belong to NPL’s acoustics department. Here they test sound and noise and the equipment to capture and measure both - 6,000 tests a year. Tested systems are deployed in areas where there’s a strong legal requirement to make sure readings are accurate. They work on everything from testing the sensitivity of microphones used in medicine to devices used to measure noise pollution. They’ve worked with at least one food manufacturer to test the loudness of the crunch of their biscuits.

Janine Avison in NPL's hemi anechoic chamber. Photo: Gavin Clarke

Tests are so stringent, the calibration work by NPL provides a reference standard used to calibrate other people's microphones. NPL claims to achieve minimal inaccuracy on sounds quieter than the level of human hearing at 0.03 dB on mics in the range of 2Hz to 25kHz. Every test that goes out of the lab can be tracked back to ensure accountability, with data queried via spreadsheet or text file.

From small mics to very large tanks

“We send mics around the world,” acoustics group higher research scientist Janine Avison told us. “We are one of 12 labs that that measure and we compare the results of our testing rigs.”

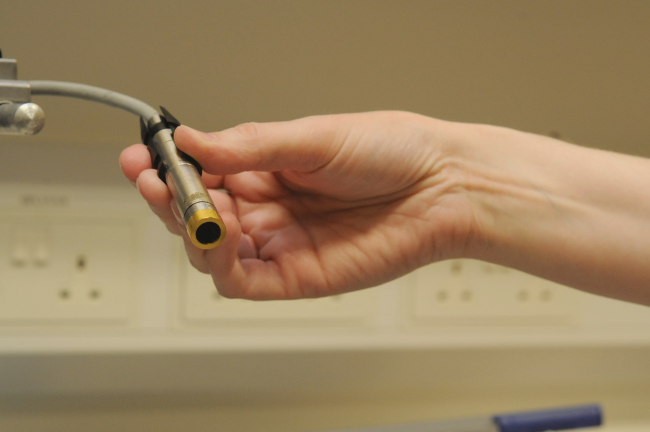

The particular room we’re in looks rather ordinary: white and spotless with work benches and sockets. In the corner sits a rig sprouting wires which relies on software built by NPL to perform pressure measurements on microphones. NPL differs from most other labs, which use an off-the-shelf reciprocity system from a Danish company called Bruel & Kjaer.

The setup measures air pressure, temperature and humidity; there’s a signal generator and two lock-in amplifiers combined with the microphones, their pre-amplifiers and their power suppliers. “Powerful” software tools are used to isolate and examine every part of the calibration in detail, Avison says.

Mics come under pressure (testing) at NPL. Photo: Gavin Clarke

Next, we visit NPL’s Large Pressure Tank, which is used to calibrate hydrophones and sonar transducers - which turn electrical signals into sound. Such equipment is used in areas like testing and measuring underwater noise pollution in the range of 1kHz and 1MHz.

NPL has two tanks but we view the larger – 5.5 metres in diameter and 5 metres deep.

This is one of those NPL laboratories I mentioned that doesn’t look like a science lab. This one looks more like the inside of a nuclear reactor chamber: a large almost empty floor space save for portals that let you peek down into deep, green-blue coloured water beneath and with various pieces of equipment ready to glide about the top.

This is a split-level lab, though, and go out the door, down a flight of stairs, open a grey-white set of doors and you find yourself squeezing into a room full of huge metal frame and massive wooden barrel. It contains the Large Pressure Tank's 80 tons of water that we were just gazing down.

The whole setup includes a submarine-line Acoustic Pressure Vessel used to simulate ocean conditions that can be pressurised to simulate ocean depths of up to 700m and temperatures of between 2˚ to 35˚C.

Sing it for a second, hear it for 30 seconds

Finally, we peek in two rooms that couldn’t be more different: the reverberation room and the hemi anechoic (echo-free) chamber.

Topside at NPL's large pressure tank, photo courtesy of NPL

The reverberation room has five sides and no parallel surfaces – the idea being to make sound waves travel further and last longer than normal. It’s a large room, 330m3 in size, and the wonky walls complete with a single lightbulb dangling down in the middle hanging from the ceiling make this feel rather like being on the set of a German Expressionist film from the 1920s.

The room’s properties are enhanced by its construction – thick concrete and coated with extra-hard plaster to help minimise sound absorption and with the whole room resting on a series of thick block-like shock absorbers and sitting inside a larger room for total isolation from outside interference.

A single B2 musical note, which has a frequency of 125Hz, can last up to 29.9 seconds in here. A mumble travels a long way and you find yourself whispering in conversation just to avoid getting an ear bashing. Avison reveals a little secret about the reverberation chamber: she sometimes sings in here.

The reverberation room is used to measure the noise absorption properties of different materials in areas like soundproofing and calibrate equipment like microphones, sound outputs, and absorption of sound.

The hemi anechoic chamber is opposite of the reverberation room. It’s an echo-free room and feels like talking while nestling beneath a duvet. The room has a clear floor space of six by six metres, with the walls and ceiling lined by sound-absorbing fibreglass wedges. Like the reverberation room, the hemi anechoic chamber floats within a large room on a series of springs and is accessed by a heavy door to isolate it further.

Tests here are conducted in the range of 125Hz to 20kHZ – from roughly the pitch of an average male voice to a range beyond the hearing of most adults. The room is used for sound power measurements, microphone testing and has been used by at least one food manufacturer test the crunch of their biscuits for loudness.

Next is another one of those laboratories that’s probably a departure from the mental picture you had of "a lab". This one is more metal or wood workshop because it is filled with benches, various construction apparatus, building materials and models of different sizes.

En route we stop the office of the man in charge - Nick McCormick, principal research scientist in NPL’s advanced engineering materials group.

Andrew Hanson beneath NPL's large pressure tank, photo: Gavin Clarke

McCormick pulls a cardboard box from under his desk and pops open the flaps to show us the contents: row upon row of hard disks, still in their shiny silver wrappers, packed in like virgin ammunition. It’s 100TB of storage.

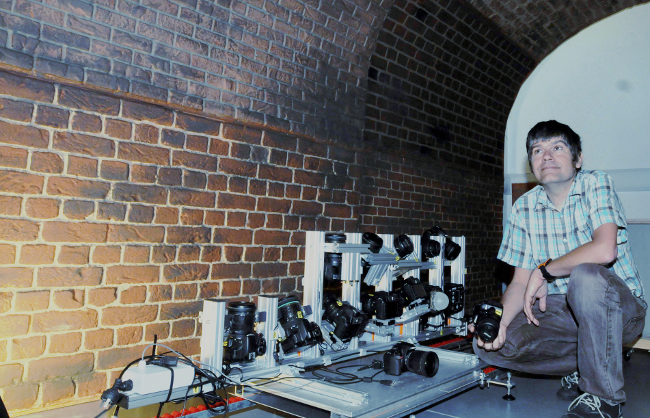

Why so much? The answer lies in McCormick’s workshop, home to a temporary mock-up of a brick underground tunnel, with rails and metal dolly sporting 12 digital single lens reflex (SLR) cameras armed with four flash guns.

This is not automated papping, but rather a project to test the wear-and-tear of buildings, specifically cracks and gaps in tunnels.

"We are trying to make tunnel inspection easier,” McCormick said. “We want to be able to compare different images and identify areas of change.”

Currently, it’s standard procedure for engineers inspecting tunnels to wander along armed with a camera on their hard hats and a stick tapping a walls playing a game of "spot the difference" and listening to the sound for signs of wear. NPL is working with Network Rail to adopt the system we're looking at. The train company has 300km of tunnels, meaning its engineers do a lot of walking and tapping and generally guessing rather than being accurate.

Crucible of time

McCormick's answer to this is a system based on digital image correlation. It involves taking lots of very large photos very quickly and using software he built to compare new and old images.

The cameras in NPL’s tunnel trolley take 12 shots per metre at 10/1000s of a second, with 24 megapixels per shot to deliver an image where one pixel covers one millimetre of tunnel, letting experts drill down to between a 10th and a 20th of a millimetre. Each image is 125 Gigapixels in size. A laser scanner on the front of the aluminium trolley measures the tunnel’s shape.

Images are aligned using software over the full field, with two images compared at the pixel and sub-pixel level using McCormick’s software. About 15,000 calculations are made per pixel in the software to compare pixels. For two tunnel scans that are 500 metres long that means about 10 trillion calculations.

McCormick juggles SLRs and software to assess tunnel wear. Photo: Gavin Clarke

McCormick's program is written in Java and runs on his Mac Pro, using 20 simultaneous computational threads on two six-core processors. NPL’s man reckons the software uses some highly efficient algorithms to run quickly and consume just 24GB of RAM. But the boffin does have a second Mac Pro in his office, plus four Mac Minis at his disposal – meaning 38 cores are available for processing.

Testing the stress on structures is an idea the mega-lab has used before – on buildings, and even on food. NPL worked with one chocolate giant to test how far the brown stuff shrank in the moulds to ensure that it fell out properly during manufacture. This process involved sprinkling an aluminium power on the surface of hot chocolate and recording the changes as the bars shrank.

We leave here and journey next to the centre of time - a room where NPL keeps the physical and digital worlds running on time: the timescales laboratory.

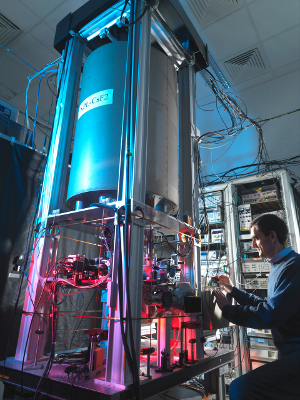

Controversial NPL physicist Louis Essen created the world’s first functioning atomic clock in 1955 - the Caesium 1. Mk 1 and its successor, the CsF2, have helped create and maintain TAI (Temps atomique international, or International Atomic Time), which is used to calculate UTC. CSF2 is an atomic fountain, a cascade of caesium atoms. The second is measured using a process that takes place when the caesium atoms are exposed to the microwaves: spin flip. The caesium atoms are resonated using microwaves until they flip at a specific frequency – 9,192,631,770 Hz; a flip defines a second.

This process is a reliable constant, making TAI and UTC more accurate than solar time, which is based on the Earth's rotation. That rotation is slowing.

An atomic-based definition of the second is perfect for digital devices and computers that need constants to function reliably just to keep time or help work out their location. The CSF2 in NPL today is 300,000 times more precise than Mk1, which - translated - means it loses just one nanosecond every two months and it has been named the most accurate atomic timepiece on the planet. As such, CSF2 is one of just six atomic clocks considered reliable enough to ensure the accuracy of UTC.

As for CSF2, it looks like an aluminium alcohol still on stilts while the room CSF2 occupies feels like a broom cupboard - tiny and windowless and nearly silent except for the ticking of tiny mechanisms on a workbench which are constantly raising and lowering their little arms to control the flow of the lasers that are used by the clock.

The CSF2 atomic clock, bedrock of universal

time. Photo courtesy of NPL

Upstairs from CSF2 is ground zero for time-keeping: the timescales laboratory. This is where the signals are prepared, sent outside NPL and monitored. It is from this room that UTC (NPL) – accurate to within 100 nano seconds (100 billionths of a second) – and the MSF Radio Time Signal are generated. The latter is the basis of the UK's civil time and is used to manage all manner of electronic devices but is best recognised as the pips heard on BBC radio. Rare outages, when they occur thanks to maintenance, are noteworthy.

The signal is sent to the Anthorn Radio Station in Cumbria from whence it is broadcast across the UK. A long-wave signal is also sent to a station in Droitwich that is broadcast by a BBC Radio 4 long-wave transmitter that dates from before WWII.

For all this not inconsiderable importance, it's a tiny and rather unassuming room: white walls, gentle lighting and a server-rack-like metal frame in the middle of the floor.

In another world, it would hold server blades. But packed in this rack is the gear to monitor the MSF time signal, check the UTC signal generated by NPL and send it up to Cumbria. A recent addition is a dedicated fixed link to the City of London's financial traders so they can time-stamp trades.

Overall, there are seven atomic clocks and four hydrogen masers. In this room there is one maser, packed into a black unit that makes it look like sound system. A further three reside in a temperature-controlled lab downstairs. The one maser is the master clock for UK time with the others on back-up duties. As one final precaution, the maser is checked against CSF2.

The timescales lab's array for monitoring

time signals, photo: Gavin Clarke

We leave the atomic-clock lab and enter another of those non-lab-looking labs. This reminds me of a Wickes’ warehouse: high ceiling, brick dust on the floor, brooms propped up in different corners.

Curiously, too, square panels of cemented brick walls have been bolted between blue metal frames and are lined up awaiting some experimentation.

Rising above this scene is the giant aluminium cube waiting to receive them – it’s contained by a round blue metal rig and controlled from a simple yellow box.

This is NPL’s Hot Box facility and the silver box dominating the room is one of NPL’s two "Guarded Hot Boxes". Hot boxes are used to measure transfer of energy as heat through various materials. The megalab has designed and built its own. This one is capable of rotating. With the addition of rotation, NPL can test this transfer, and thereby the energy efficiency of materials, in any orientation: inserted materials can be warm on top and cold underneath, vice versa, or a plain old left-to-right shift.

Thinking outside the static hot box

NPL has been testing heat transfer through materials since the 1970s and structures since the 1980s, but this rotating box was finished in 2002.

Ray Williams, principal research scientist in the materials processing and performance group, tells us the purpose of this rig is get a grip on the energy efficiencies of different building materials - hence all those bricks lined up waiting for testing. It’s designed to put some solid numbers behind claims by the construction sector on the energy efficiency of buildings and support the Government’s green deal.

“Every wall, roof and floor in the country has been calculated,” Williams tells us, meaning the heat-leaking properties of walls and roofs in the UK have been arrived at using the different mathematical formula. Not in the hot box. “We measure the difference... we want to get the actual value of a brick wall.”

Ray Williams controls the rotating hot box. Photo: Gavin Clarke

How does this hot box work? It contains two chambers, whose temperatures can range from 22°C to a nippy –10°C. Materials are placed in the centre and measurements taken of the direction and rate of energy flow.

The hot box contains more than 140 sensors to log 250 channels of data every two hours on air temperature, airflow rates, fan power, transfer coefficient and thermal transmittance, as well as conductance and resistance. Data is logged using a program written by NPL that calculates all the parameters and measures thermal equilibrium. Data is stored in a text file and recalculated using an Excel spreadsheet.

It can take up to three days just for the materials to reach a state of equilibrium – where they’d stopped absorbing energy as heat for tests to start. Some tests have taken up to three weeks to conduct – as in the case of insulated concrete.

Our tour finishes where so much of this began, in 1875 – with the kilogram. We're standing in a lab full of waist-high work benches that is spotlessly clean and seems impossibly bright. I find myself blinking. There are weights and measures everywhere, lined up in neat rows in wooden trays and under the cover of glass or perspex. We are here to see kilogram mass No 18 and its possible replacement, a silicon sphere.

Scientific researcher Stuart Davidson holds them in purple gloved hands in this exceptionally clean environment. The gloves are designed to keep them free of contaminating fingerprints that might inadvertently alter their mass and thereby change the official mass as we know and use it.

NPL's copy of the kilogram mass standard and the Avogadro silicon sphere. Photo: Gavin Clarke

The kilogram was one of the two first base units to be defined along with the metre - created following the signing of the Convention du Mètre (Treaty of the Metre) and formation of the Bureau of Weights and Measures (BIPM) in 1875.

The treaty was the result of years of pushing by France for an internationally recognised system of weights and measures - it had advocated this since the 1789 revolution. Pre-revolutionary France had had a system of 250,000 weights and measures that varied between villages, towns, cities and regions. It was chaotic and crippling for the economy. Britain had an archaic system, too, dating back to Roman times. Britain eventually signed up to the Convention in 1884 with the help of the Royal Society.

The second, kelvin, ampere, candela and mole were ratified as standards in 1889. Over the years they've all been become atomic standards similar to the metre (wavelength) and have been rebranded as SI standards. Only the kilogram is holding out – the last to still be officially measured using a physical object. It's that mass that squats under glass at the BIPM outside. It has held out despite decades of work to convert it into a atomic equation.

NPL worked on a Watt Balance to express the kilogram as electrical current that plays on mass, voltage and movement. That work has moved to Canada and is still on going with NIST also working on its own, separate Watt Balance.

So far, the difference in results between the two has been too great for an official standard - 250 parts per billion. The General Conference on Weights and Measures in Paris is overseeing the process and waiting to adjudicate. It wants accuracy of 20 parts per billion. To give you an idea of what’s at stake, the mass in Paris is believed to have altered by just 50 parts per billion during its lifetime.

How do you weigh a Concorde? Using carefully calibrated scales... Photo courtesy of NPL

Work on the Avogadro Constant, meanwhile, is scheduled to finish next year.

Look out for the next open day. This being a working facility and not generally open to the public, there’s no café you can pop into for refreshments. No shop either. You can, though, walk into Teddington, which has plenty of restaurants and cafes – and shopping. A little further afield, but still close, is Kingston-upon-Thames. Should you chose to linger, there is a hotel – a Travelodge – next to the station, and you could pack NPL in with a family trip to Bushy Park or Hampton Court, too.

Whether you're chewing on your lunch or riding the train out after, marvel and be thankful for NPL. Its men and women are sweating the small stuff so you don't have to. ®

GPS

51.427120, -0.344186

Postcode

TW11 0LW

Getting there

By train: Between 30-40 minutes from London Waterloo to Teddington, then a short walk or even shorter bus ride - 285 or R68 to Hampton Hill.

By car: the A313 north of Kingston-upon-Thames

Entry

Check website for open-day events