This article is more than 1 year old

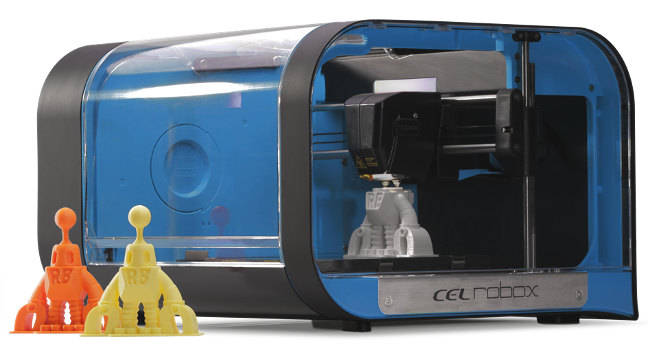

Robox: How good could a sub-£1k 3D printer be?

Home-3D-printed parts are inherently weak, BUT...

Keep that nozzle clean

Once sent, you can unplug the USB cable, but you won’t have any status info. There is no display on the printer at all, only a nicely coloured light at the back. I’d prefer a two-line LCD rather than a purple light, but then again you are always going to have a PC plugged in.

Having a UI to send parts from a phone, like some printers? How is that going to work? I think the software supports plenty of PC OSes, so there are no problems there. It gives you all sorts of options, such as scale, orientation, or printing multiple objects at once. Even more options appear when you know how to get to them, covering wall thickness, print speeds, temperatures, fill patterns, calibration, etc.

When you hit go, the printer wakes up and first brings the build platform up to temperature, then the nozzles. This does take a few minutes, but there are nice graphs of temperature to show you it is busy, it also shows remaining build time and then levels the build platform every time, a key issue with this style of printer. It does this by going N-S-E W on the base and tapping the nozzle at each point.

Unfortunately, it goes back to exactly the same point each time, and if there is a little bit of plastic crud on the base from last time, or on the nozzle, then this ruins the calibration. You quickly learn to clean these four points and the nozzles before each print. Then it runs two test extrusions out to make sure it is all ok, these again need cleaning off each time, something not mentioned.

CEL supply a pack of alcohol wipes (like screen cleaning wipes), which you will find you go through very quickly. They don’t work well on a hot base, unfortunately you have to leave it to cool down before cleaning it or the alcohol evaporates before it gets chance to cleans.

This seemed to be the most critical part, getting the base clean and getting the first layer to stick. I’ve read about people using masking tape, hairspray, and all sorts on other machines. Nothing like this is necessary. Just a clean base, properly calibrated. Sometimes it doesn’t go smoothly, but you find out fairly quickly.

I’m sure if I had the printer for another day then I would have got better, but I did have some issues. Good calibration and a clean base seem to be key. I also got carried away, as my first couple of prints went far too easily. When I started printing bigger parts for the quads I had a few more problems. But, I only had the printer for just over a day, all of this takes time. But from what I have heard, this is a huge advance over older printers.

Another advantage of the heated build platter and enclosed box is getting the parts off when they finish. If you wait for it to cool, then the parts just lift off. I was amazed as to how easy it was. And it also means the parts don’t warp as much when they cool, just look for videos of other printers doing this.

Small, reasonably intricate projects such as these are well suited to the Robox

So, after designing, printing, re-designing and re-printing, what are my views? 3D printing is not for everyone and it is changing at a huge rate. It isn’t elitist, but I think you must have something you want to design or build that is new, or unique.

If you can buy something, go and buy it. It will be quicker and cheaper with a better product. But if that something doesn’t exist, yet or you can’t buy it anywhere, then this might be able to make it. I guess £800 is still a lot of money, but to put it into perspective, it's considerably less in real terms than I paid for my first DeskJet all those years ago. ®