Original URL: https://www.theregister.com/2014/02/12/archaeologic_amstrad_cpc_464/

You’re NOT fired: The story of Amstrad’s amazing CPC 464

30 years ago, a budget micro shocked a nation - with how good it was

Posted in Personal Tech, 12th February 2014 10:01 GMT

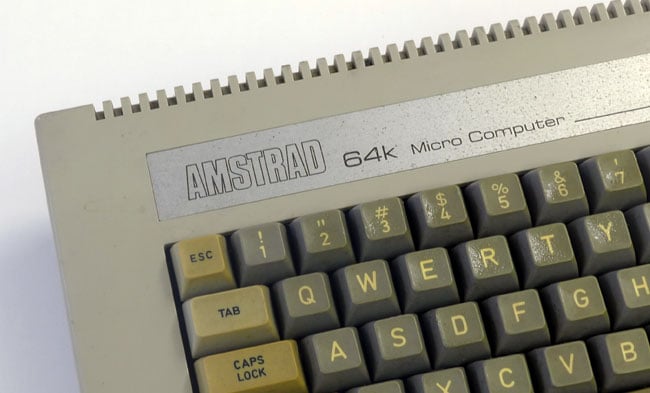

Archaeologic It was a home computer that embodied so many contradictions. It was launched months after the British microcomputer boom of the early 1980s had peaked. It was a rush job: the machine that was revealed to the press in the Spring of 1984 hadn’t even existed nine months previously. It was one of the best-produced British micros of its era, yet it came from a company then known only for dirt-cheap hi-fi products. It shipped when its manufacturer said it would.

The invite to the launch, which took place at 11.30am on Thursday, 12 April 1984 at the Westminster School, London, teased attendees by promising they would get to “meet Einstein, Archimedes, William Shakespeare, Monet and Ravel”. In fact, it was the Amstrad CPC 464 - "CPC" for "Colour Personal Computer" - to which they were introduced.

Pre-release styling: one of the 464 prototypes, courtesy of Simon Rockman

It’s not quite clear when Amstrad decided to enter the home computer market. Throughout the early 1980s, the company’s boss, Alan Sugar – then long before his elevation to the peerage and his regular TV appearances – seemed generally dismissive of the new technology. Not because it wasn’t any good, but because he didn’t think the ordinary folk who made up Amstrad’s customer base wanted or needed it.

If that ever really was his view and not an example of a canny businessman’s way of steering attention away from what he was really thinking, he changed his mind some time during 1982, quite possibly following the arrival of the Sinclair ZX Spectrum, which had been launched in April that year but took some months to arrive in the shops.

The Spectrum wasn’t Britain’s first colour computer, nor the first for home use, but it did demonstrate that there was a massive untapped market for a good-looking, low-cost colour machine. Sugar was not alone in being inspired by the Sinclair Spectrum to enter the home computer business. This was a time of "whatever you ship, you will sell". What player in the electronics business could resist? Especially now that, as Sugar notes in his 2010 autobiography, What You See is What You Get, sales of Amstrad’s consumer electronics were beginning to plateau. “We needed to move on and find another sector or product to bring us back to profit growth,” he wrote.

Work started on the Amstrad home computer early in 1983. Amstrad engineer Ivor Spital, who’d been with the firm from the beginning, was asked to provide a competitive analysis of the machines an Amstrad computer would go up against. He bought a pile of available models to see how they all worked, what set-up they required, what extras they came with and what it cost to make them.

Come and see a new computer launched: the CPC 464 introduction invitation

The upshot of Ivor’s investigation was that Amstrad could and should enter the market, and play to its strengths: the integration of low-cost hardware into a product that would be sold at an affordable, impulse-purchase price. Amstrad was an early proponent of all-in-one hi-fi units shipped with bundled speakers. One idea, that the company might re-badge an Asian Apple II clone, was rejected.

“My concept was simple: Mum and Dad don’t want little Johnny taking over the TV set, so our computer should come with its own monitor, have a full-sized keyboard and a built-in cassette mechanism for loading software and hit a target price of £199,” wrote Sugar in 2010. “This way, little Johnny could have it in his bedroom, freeing up the family TV.”

Amstrad lacked expertise in computer hardware and software, so it would commission contractors for that work but create the casing itself, under the guidance of one of Sugar’s key lieutenants: Bob Watkins, who’d joined Amstrad years back as a draughtsman and designer but by now become the company’s technical and manufacturing director.

Soon, Amstrad not only had the machine’s casing designed, but it had tooled up the necessary mouldings to put the computer’s shell into production. The keyboard and cassette mechanism had been chosen. They had defined where the ports would go, and where holes would need drilling in the PCB to allow the screws that held the two halves of the casing together to pass through. All the company’s manufacturing team had to do now was wait for the motherboard and the software that would run on it.

The first development team

Around April 1983, development partners were found: “A couple of long-haired hippies who had helped us out previously,” wrote Sugar in his autobiography. “They claimed they would easily be able to design a PCB to go inside this beautiful exterior hardware.” More to the point, they said they could do it in a very short period of time.

Work began on a device based on the 6502 processor then being used in the BBC Micro, the Commodore 64 and the Apple II, and judged in the competitive analysis to be more highly regarded than the Z80. But as spring rolled into summer, it became clear the development of the hardware and software were not going well. There was no ROM chip because there was no software to put in it. And the designers appear to have created a system based on dozens of chips, not realising that many of them could be integrated into a custom component for a fraction of the cost.

Five years later, it was revealed that at one of the two-man development team had found himself entirely unable to cope with the pressure of Amstrad’s deadline and abruptly resigned. He returned the advance on his fee that Amstrad had already paid and turned his back on the project.

Sugar’s autobiography provides a little more detail: the developer in question was one “Paul Kelly, the lead rocket scientist of the dynamic duo”, and Sugar says Kelly simply went AWOL. Kelly’s father, it seems, had discovered the young man sprawled on the floor with exhaustion and had packed him off to where he could recuperate.

The truth was, Kelly and his colleague had bitten off more than they could chew. Their casual "oh, we can do it in a month" claim, even if they hadn’t meant it as a specific deadline, had been taken at face value by both Alan Sugar and Bob Watkins. When the month was up, Watkins, not unreasonably, started asking them where the software was and when it would be ready. Kelly, finding the work tougher than he’d imagined, was unable to provide a clear answer. That only increased the pressure he was undoubtedly feeling. And what, he must have wondered, was he going to do if he couldn’t make it work at all?

Kelly appears to have recovered from his collapse, because Sugar says he eventually supplied some software in machine code form ready to be burned to ROM. But, the Amstrad chief claims, the software was “garbage”, just a meaningless collection of bytes sufficiently long to fill the chip. It was “just some rubbish to keep Bob quiet”, and it wasn’t until Toshiba burned it to ROM that the tactic was exposed. Sugar doesn’t say so, but it’s hard to imagine he or Watkins could have done anything at this stage but take the project away from the “hippies” and put it in more capable hands.

Development team two

Enter Roland Perry and William Poel. These two men would become synonymous with Amstrad’s entry and rapid expansion into the UK computer market, not just its efforts in home computing but its even more successful jump into the world of business micros. At this point, though, they were working for themselves at Ambit International, a Brentwood, Essex-based component supplier and jobbing hardware design consultancy founded by Poel.

Perry and Poel had been pals since childhood, and they had together developed an interest in radio and electronics at secondary school during the late 1960s. In 1971, their paths diverged: Roland went off to Cambridge University to further his education; William stayed in Brentwood and entered the world of work. But they both kept in touch. In 1972, Poel established Ambit – largely, says Perry, to get access to kit that was difficult for folk outside the trade to obtain: “He’d order a hundred devices, keep one for himself and sell the rest.”

Perry, meanwhile, scouted Cambridge University’s electronics and radio societies to find enthusiasts able to devise and write up projects for which Poel would offer free parts in exchange for the right to pitch the designs to electronics magazines. Readers interested in building the radio receiver, car alarm, metal detector or whatever would be invited to send a cheque to Ambit for all the necessary bits. This was a common practice among the component suppliers of the time: home computer pioneer John Miller-Kirkpatrick’s Bywood Electronics thrived on it. So did Research Machines’ subsidiary, Sintel.

After university, and with an MA in Engineering and Management Studies under his belt, Roland Perry gravitated back to Brentwood and Ambit, where he became General Manager. However, an increasing interest in the emerging microcomputer business - he recalls regular visits from the major processor suppliers pitching their new development kits; Motorola’s 6800-based Exorciser, for instance - led him to take a maintenance training job in 1977 at nationalised computing giant ICL. But he soon found the firm’s old-fashioned bureaucratic and stiff company culture not to his taste and in 1978 he left to join microcomputer supplier Sintrom to run its newly opened MicroShop outlet, essentially a showroom for the dealership’s business-centric computer range, including some of the first Apple IIs and Commodore Pets in the UK.

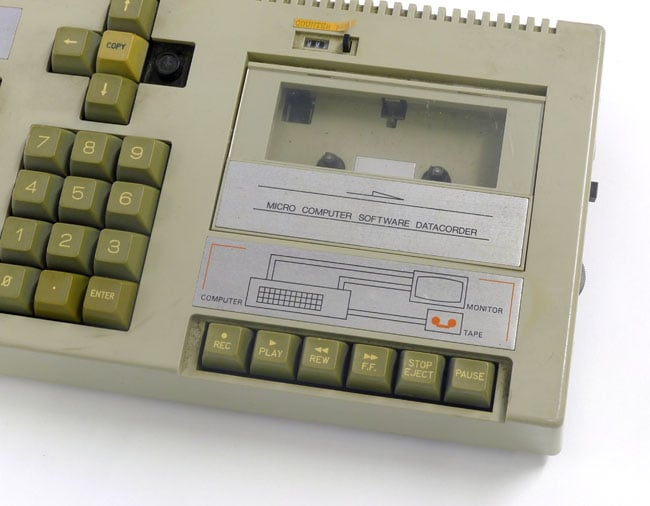

The cassette drive was specified before work started on the PCB

Sintrom quickly progressed to making its own machines, and when, at some point in the early 1980s, William Poel said he wanted to buy one to manage Ambit’s stock control process, Perry did what he’d told many another Sintrom customer he would not: he left Sintrom to maintain Ambit’s new system and to write its software.

By this stage, Ambit was a large, successful company. It had even extended its reach into contract design, with an emphasis on radio for which it had developed working relationships with many of Britain’s high-end hi-fi companies. But not just top-of-the-line firms: Amstrad’s Bob Watkins approached Ambit for help getting a CB radio offering to work, which it had.

No wonder, then, that Watkins immediately thought of Poel as a possible troubleshooter when the Amstrad home computer project ground to halt in the Summer of 1983. Ambit’s 40-odd staff were engaged in the firm’s annual stock check – for which it shut for three days at the start of August – when Watkins knocked on the door to see if they could help.

Watkins asked Poel what could be done. Poel suggested he and Perry be hired as consultants. They would deliver a working micro with software to Amstrad, ready to go inside the casing that had already been designed.

“Amstrad’s forte was getting tooling, injection moulding and conventional electronics done. By August that year they’d got a fully finished keyboard in a case, they’d got monitors, they’d got a cassette drive all fitted - you pressed the Eject button and out popped the tape - all like a completely finished computer,” says Perry.

“The only problem was, they didn’t have the motherboard. They even knew exactly what shape it had to be: the connectors were at the back, there were holes for spurs on two halves of the case to fit through the board, all of those in exact positions. So you needed a bit of Swiss-cheese motherboard to fit into the empty case.”

Recruiting the experts

With the Amstrad micro development contract in Ambit’s hands, Perry drove straight to Cambridge and approached many of his contacts in the local community of electronics and technology companies to seek someone who could pick up the work done on the machine and finish it.

“I knew a lot of people working in this stuff, and I knew exactly what was necessary in terms of the components: you need a Basic interpreter, you need a sound generator, you need a certain resolution on the screen. A lot of computers could only do four colours at a limited resolution, and I wanted to do better than that,” Roland remembers.

“So I literally embarked on a road trip where I went round and talked to all my contacts working in computer companies and design contractors, and showed them the case with the keyboard and tape drive and asked what they thought they could do with it.”

First, the software. Some companies he contacted were not interested, or felt they lacked the expertise to write a Basic interpreter. Others were too busy: a contact at software house GST said they were going hell-for-leather writing a 68008-based operating system and application suite for a new machine Sinclair was working on; five months later the computer would be launched as the QL, though not with GST’s OS or applications on board.

Then a pal at Acorn – Howard Fisher, who was also one of Perry’s school chums – suggested Amstrad’s man travel to Dorking, Surrey and pay a call on Locomotive Software, which had just completed a Basic project for the BBC Micro maker.

“We first first saw the hardware in August 1983 when Roland showed it to us in my front room,“ recalled Locomotive co-founder Richard Clayton in 2012. “He had Letraset-ed the word ‘Arnold’ on the case, but when we opened it up ‘Amstrad’ was printed quite clearly on the circuit board.”

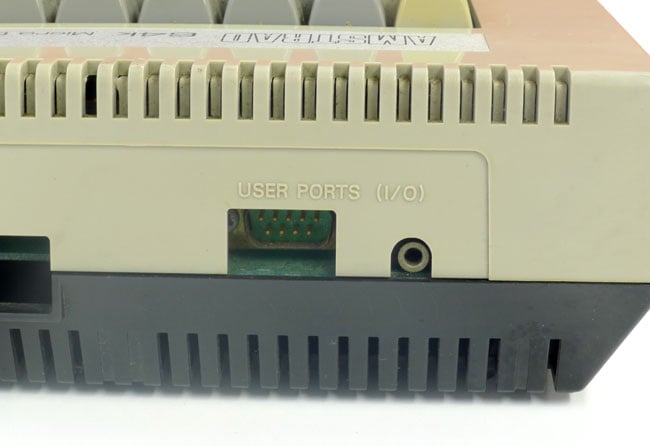

These became the joystick port and headphone jacks in the final version

Why "Arnold"? That was William Poel’s idea; only later, Roland insists, was it found to be an anagram of his first name. Amstrad’s design team had long since completed the computer’s outer casing, complete with keyboard, cursor keys, numeric pad, tape drive and controls, gaps in the back for ports, and even the company logo, positioned just above the keyboard.

Obsessed as it was with commercial confidentiality, there was no way Amstrad would be happy with Perry’s interviewees knowing what it was up to, so Perry used nail varnish remover to erase the brand and put Arnold in its place. Poel suggested the name: it would encourage anyone who saw the box to think of Arnold Weinstock, then head of industrial giant GEC, and so think that company was making the box Perry was showing.

That made people comfortable, he says, because they knew GEC had all sorts of little businesses and that one of them might very well be developing a home computer. Who else, then, could the “big British company” Perry was representing but could not name be? Having made the intended assumption, they were all the more ready to hear Roland out. In all, he talked to about a dozen companies about the project.

Richard Clayton says he’d never heard of Amstrad at that point, but it didn’t prevent him signing up to write a Basic interpreter for the new machine. Locomotive was an ideal candidate for the work. Although the company had only been in existence since 14 February that year, its two principals, Clayton and Chris Hall, had already been commissioned by Acorn to write a version of Basic for the BBC Micro’s add-on Z80 processor, for which Fisher was compiling a bundle of business software. Their Mallard Basic, named because of its speed, had been finished and was undergoing final bug-testing when Perry came to call.

Richard Clayton had been a maths undergraduate at Cambridge when the combination of failing his second year exams and becoming involved in protests against college room rent increases saw him ejected from the university. He’d planned to switch to computer science in his third year but now he went to work instead, joining ICL in Bracknell as a programmer. That was during the Summer of 1973; 18 months later he was poached by a word processor hardware company, Data Recall, for whom Clayton’s college pal, David Collier, had gone to work after graduation. Collier was lead programmer; he wanted Clayton as his number two.

At that time, Data Recall was based in the West London suburb of Boston Manor. Clayton needed to move, and an ICL acquaintance, Chris Hall, lent him a a spare room until he’d found a place of his own. Clayton was later able to repay the favour: when David Collier was dismissed from Data Recall, Clayton got his job and asked for Hall to be hired too. During his time at Data Recall during the mid-1970s, Clayton took his degree, in computer science, at Manchester.

By 1980, Chris Hall had tired of working on software for word processing hardware and quit to go into consultancy. But he kept in touch with Richard Clayton, and in 1982 the pair decided to go into business together. The IBM PC, which had been launched in the US on 12 August 1981, had by now finally gone on sale in the UK. Clayton and Hall’s first project was an accelerator board for the machine, based on a National Semiconductor 16032 chip and a Pascal runtime.

And then an old college friend, Howard Fisher, now working for Acorn, came knocking. He wanted a Basic that would run on the Z80, cost rather less than the price Microsoft had quoted him, and could be coded with an Indexed Sequential Access Method (ISAM) indexed file system so he didn’t need to buy a database application too.

The two programmers, now trading as Locomotive Software, hired a third, Paul Overell, to help out. Overell wrote the file system. They achieved what they had promised Fisher, who was therefore happy to recommend them to Roland Perry. During the second or third week of August, he formally offered Locomotive the Amstrad gig.

Locomotive’s complete Basic interpreter was written in Z80 assembly language. Plan A was to simply finish the existing hardware and write the software, says Perry. Yes, the Locomotive boys told him at the time, they could convert their Basic to the native machine code of the 6502 processor but they might not be able to do so and make all the necessary alterations - adding graphics, colour, sound and so forth, removing the ISAM file system - by the start of December, the deadline Amstrad had imposed upon Ambit. Why not, they suggested, simply switch to the Z80? That would allow Locomotive to tweak the work it had already done and give it time to expand and enhance its Basic for home market.

The engineer

While working at Data Recall, Clayton and Hall knew a young hardware engineer called Mark-Eric Jones who happened to be the owner’s son but, more to the point, was an electronics wizard with a keen interest in microprocessor technology. Converting his father’s word processing systems to operate using microprocessors – they originally contained boards of wired transistors, not even Transistor–transistor logic (TTL) chips – Jones junior had received one of the first Intel 8080 chips to arrive in Britain.

Young Jones had been eagerly experimenting with electronics since his teens, and he duly went up to Trinity College Cambridge to study Electrical Sciences, an engineering course with an emphasis on electronics in the third year. But long before then, Jones – "Mej" to his pals – was helping his father improve Data Recall’s word processors and increasing his pocket money doing system repair work for a dealership which sold computers manufactured by Israeli technology company Elbit Systems.

In 1976, shortly after graduating, Jones found himself inheriting a project designing and improving the microprocessor-based electronics on which a series of early industrial robots were being constructed. The manufacturer’s lead designer, who knew Mej well, had accepted a job in the States and suggested his friend be contracted as his replacement. Barely out of college, Jones founded MEJ Electronics and contracted his services to the robot maker, Data Recall and, over time, others. By 1983, when Roland Perry met him for the first time, MEJ had expanded into a successful hardware design business.

“Roland turned up with a PCB with a whole load of chips on it,” remembers Mej. “There were clearly some issues with the board, to put it mildly. I looked at it and noticed that some of the chips didn’t have the power supply connected to them, and I thought ‘well this is not going to be able to work’. The were clearly some errors on it. It may have been that some of those could have quickly been solved, who knows, but if there were things I could find in such a short time, perhaps there were other problems that would take longer to uncover.

“I do recall an uneasy feeling about the design. Now I suppose all designers feel that if they look at someone else’s design, but this went further than normal. I had no 6502 experience but had done many Z80 designs, so as far as I was concerned it was no-brainer to switch to the Z80.”

Expansion ports, to sell punters more kit

Hands were shaken, deals were struck. Amstrad’s approval was sought and granted. Toward the end of August, a strict development schedule was agreed. From the beginning of September, Locomotive had just over 12 weeks to produce working code; that would take up to the start of December. At the same time, Jones would build a suitable motherboard to the agreed spec and able to fit inside Amstrad’s casing.

“From early September onwards we had a whiteboard and each week we changed the number of weeks to go, so we knew exactly where we stood,” recalled Richard Clayton in 2012. “Lo and behold, it went on the arranged day and it was ROM’ed.”

“We handed over our finished software 14 weeks ago,” said Chris Hall in a 1984 interview with Popular Computing Weekly and conducted around the time of the April launch. “The machines at the launch had finished ROMs in them.”

Clayton describes the coders’ approach to their new interpreter: “We were very influenced by what Acorn had done with BBC Basic, but we wanted to avoid the cryptic *FX stuff as far as possible, so we added lots of keywords. We also wanted to be able to show off what the machine could do, graphics, sound etc. from the Basic, so you could get fancy things like synchronised music and movement without having to learn to program it in assembler.”

Specifying the software

Clayton and Hall, along with new recruits Bruce Godden and Tony Bush who had been hired on the back of the Amstrad contract, decided to architect the system software as a slightly modified version of its Basic interpreter which would sit on top of modular firmware. The firmware would deliver the additional functionality required by the new machine.

The firmware was organised into five functional modules: the screen (allocated to Paul Overell), the cassette storage (Tony Bush), the drawing routines (Bruce Godden), the floating-point arithmetic (Chris Hall) and the core real-time OS (also Hall). The reasons for the segmentation? To keep certain functions clearly separate and organised, of course, but also because it allowed the team members to more easily work in parallel and because each part of the firmware would fit on the 5.25-inch floppy disk in each development machine, says Clayton today.

“We tried to keep a firm distinction between the firmware and the Basic,” explained Chris Hall in 1984. “The Basic simply takes the commands keyed in, packs them up and passes them to the firmware. The HiSoft Pascal written for the machine, for example, has all the graphics and sound facilities that the Basic does.

“We also wanted to avoid ‘magic numbers’ in the Basic. The Commodore 64 has some very good hardware features but, without Simon’s Basic [an optional add-on to the built-in interpreter] you have to spend your time POKE-ing away with magic numbers.”

The goal, Hall said, was to make Arnold as easy to program as possible. “After all, even an experienced programmer, faced with a series of POKEs to various machine code addresses written some time ago, may have trouble working out what is going on.

“Anybody writing software for the Amstrad should never need to go near the hardware. The only possible point would be if you want particularly fast and flashy screen routines. In this case we decided that it wasn’t appropriate to provide generalised routines.”

Later, software houses would be specifically asked by Amstrad to use the firmware toolbox rather than write their own routines for key tasks, a common approach today, but back then far less used. There were other innovations the team made:

“We wanted to the machine to have separate text and graphics windows,” said Hall in 1984. “We thought one text window was a bit mean so we have got eight. The text windows are tied up with the eight text streams. Each stream has its own window, its own cursor and its own PEN and PAPER commands. You select a stream which you can then write too - and it will plonk it out in that [window].”

Another novel feature - and again one intended to allow Arnold to be fully functional in Basic without having to fall back on machine code routines - was the addition of interrupt controls to the high-level language. The AFTER and EVERY commands allowed program sub-routines to be triggered at 1/50th of a second intervals. It wasn’t a unique function, but only one other micro, the Japanese Sord M5, offered this kind of control.

Constructing a personal computer

Some 16KB of Arnold’s 64KB of RAM was dedicated to the screen and 5KB for the OS, leaving 42KB for the user. The 32KB ROM was segmented into two 16KB blocks one for the modified Mallard Basic, the other for the new code, though the Basic overlapped a little, Clayton explains today. Paging hardware flipped the 16KB section in use at the time in and out of the Z80A’s memory map in alternation with the video memory. The Basic interpreter was modified so that the part held in the second 16KB of ROM wasn’t required when the first was page in.

The screen memory was used to hold the display data according to the three modes Arnold provided: numbered 0, 1 and 2. The latter was the hi-res 640 x 200, two-colour mode, with the resolution falling to 320 x 200 and 160 x 200 in the other two modes, though the number of usable colours, selected from a palette of 27, rose to four and then 16.

The three modes could incorporate text too, at 20 x 25 characters, 40 x 25 and 80 x 25, respectively. One neat touch: swapping one of the 27 colours in and out of the available palette of 16, four or two caused the on-screen colours to change immediately, allowing some clever colour tricks to be performed in software.

“The monitor is a pixel VDU - the simplest sort,” said Chris Hall in 1984. “When you do the sums you find the Amstrad has to be the way it is. It’s a straightforward 16KB of memory for the display... You can ‘suck’ 16KB from RAM just fast enough to refresh the screen.”

Without working hardware, the Locomotive team had to make certain assumptions about what the machine’s capabilities would be. “We had an idea of what price the machine was going to be sold for, which set the parameters for the hardware,” said Hall. “We couldn’t knock out something ‘noddy’. On the other hand, we didn’t have time to produce a QL from scratch."

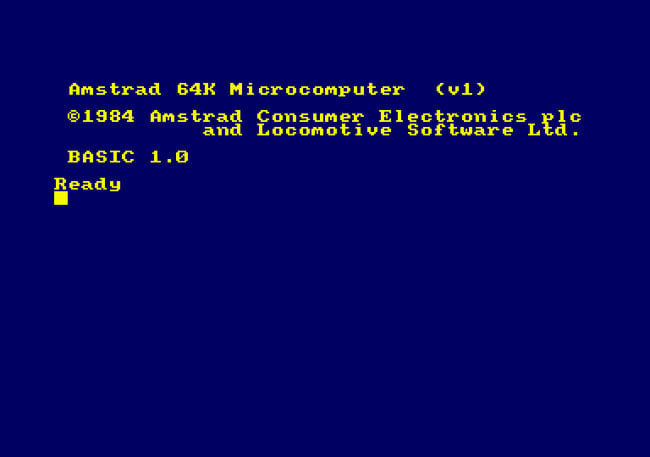

Booting up: the CPC 464’s initial screen

Hall adds: “There were a number of constraints which came from Amstrad’s original thinking: the casing and keyboard and the inclusion of a cassette recorder and a monitor. That was all settled and had to be taken on. A Centronics port seemed appropriate for a printer. Having a built-in cassette player made life easier because its electronics are a bit special. Add a custom gate array and there you have the machine.”

That was the agreed specification, and that’s what Mark-Eric Jones and fellow hardware designer Roger Hurrey worked to create while the Locomotive team were writing the software. Jones worked on the main board, Hurrey on the gate array. Hurrey was another one-time Data Recall colleague of Jones, Clayton and Hall, and had in fact designed the ill-fated IBM PC accelerator board under contract to Locomotive.

Mej remembers the specification process: “Amstrad was basically saying, ‘We want to get this thing into production quickly, and we have certain key requirements’. They decided for marketing reasons, the most important thing was to say that it had 64KB of memory and that it had lots of colours. They threw in one hand grenade: they said, ‘Oh we’ve actually ordered quite a lot of the components, and if you can use the same components that would be very helpful’.

"In the end we used a very different set of components but helped solve the commercial problem of having already placed orders with suppliers by getting them to order from those same suppliers.”

The original 6502-based board didn’t incorporate any custom silicon. “We decided to use a gate array to make a lot more functionality available than we could have done otherwise. By having a lot of logic - about 1200 gates - embedded into a gate array, it had a lot more functions that it could possibly have had in the original version which was shown to us and which didn’t have anything like that. That allowed better video, way beyond what they were proposing for the original board.”

Managing the contractors

There was a lot of pro-active hassling, remembers Roland Perry. “I’d go out on a Friday evening and pace up and down on someone’s premises and say, ‘Have you finished? I want to this ROM or this chip layout.’ And they’d say, ‘We’re not quite finished yet, can we deliver it to you at nine o’clock on Monday morning?’ I’d say, ‘No, because the person who is going to work on it next is starting at nine o’clock tomorrow!’ Our timetable was so tight everyone was working weekends.”

Perry had done critical path analysis work at University, and this he now applied to help him map out a timetable for his two contractors, Locomotive and MEJ: “If we throw everything we’ve got at this, and if the consultants give it top priority, and we schedule it down to the wire, we can get it done.

“The rush was because of the annual cycle of Amstrad product development. Amstrad wanted to have product in the shops at Christmas. If they’re going to be in the shops at Christmas, they have to be on Dixons’ shelves in September, which meant they had to be on the boat from the Far East six weeks before that, which meant they had to be being built in the factory a month before that.

“We had to have a timeline that meant you could launch the product around Easter, which meant you had to have a reasonable number of working prototypes, preferably built in the proper factory, which meant that the people with the factory have got to have built a production line, and they wouldn’t do that unless they knew that it was going to work and not vapourware. So drop dead time was the first week in December, when you went to the Far East and showed them what you wanted them to build.”

“It was a time of intense work,” recalls Mark-Eric Jones. “We were living off frozen pizzas more or less, and every evening working late into the night. This was largely happening in the house I owned at the time. Roger was there with us. We had a drawing board out. There wasn’t any schematic capture back then so it was all drawn with pencil on paper, and that’s how the design was evolving. We were building prototypes in the spare bedroom. My wife – she was my girlfriend at the time – was hauled in to solder prototype PCBs.”

Jones and Hurrey made rapid progress on the Arnold hardware. Locomotive got to look at the the first working hardware at the end of October 1983, though at this stage the machine’s ULA chip was not ready so it had been replicated in circuit board form so the software guys knew exactly what it could and couldn’t do, and could test working hardware. This board, designed and built by Hurrey, was dubbed the "Gate Array Simulator" – or “the Gas Board”, for short. The PCB layout was made, from Mej’s schematics, either by Alan Jones, a contractor the engineer had used for many other circuit board projects in the past, or one of Ambit’s contractors.

The ULA would not be completed until February 1984, but the PCB layout was done and dusted during November 1983. The following month, with the Basic and firmware finalised but for four weeks’ bug spotting and squashing, Roland Perry and William Poel began sending out hand-built Arnold prototypes, each a laden PCB with the Gas Board riding piggyback and with a small doohickey comprising 32KB of battery-backed RAM to hold the firmware in place of expensive EEPROMs, to key software houses. Alan Sugar had insisted that the machine would need to have plenty of games ready at launch, perhaps as many as 50.

Getting working kit out to developers nice and early was a masterstroke. Where other manufacturers didn’t tell developers about new machines until the hardware was formally launched, Perry and Poel’s approach put working kit in coders’ hands and quickly won Amstrad the thumbs up from almost all of the major games developers. In turn, that meant a ready supply of software when the computer finally went on sale. It also ensured Alan Sugar would have games to show when the computer was launched.

Perry took on Sally Tyler to manage the logistics of getting these confidential prototypes out to developers and away from prying eyes. She was almost certainly successful, but nothing could really prevent the odd leak. In January 1984, Popular Computing Weekly reported that it had heard that Amstrad will offer a sub-£200 micro late the following Spring as “a direct competitor for the new Elan”. The report said the new machine would have 64KB RAM expandable to 4MB, include a full-travel keyboard with separate numeric pad, sport “similar graphics to the BBC” and have a three-channel, six-octave sound system. It would have a Centronics interface but no RS232, the paper reported. Its claims were surprisingly accurate.

For its part, Amstrad wasn’t exactly keeping mum either. Alliterative marketing manager Malcolm Miller told Your Computer in February that the company was working on a new machine and that “what we’re going to offer will be extremely successful [because] we have tremendous experience in marketing”.

Or, rather, the sales skills applied by Amstrad senior staff to persuade major high street retail chains Boots, Comet, Dixons and Rumbelows to commit to buying 100,000 machines in total. Combined, those orders underwrote Amstrad’s production and development costs.

ULA agley

The machine’s PCB layout, the software and the casing mouldings were all sent out to Amstrad’s production partner in South Korea, Orion, and with the ULA signed off early in February, chips could be sent over for assembly too. Orion would bill Amstrad cost plus five per cent for each machine that rolled off its assembly lines. With everything ready in March 1984, there was time for production to be tweaked for greater yields before the machines had to be in the shops.

Well, almost. According to Sugar, Ferranti, the leading British manufacturer of custom chips and the firm selected to produce Arnold’s ULA, let them down “at the eleventh hour”. Roland Perry says the problems centred on the semiconductor process Ferranti used; the ULA design was attempting to achieve two things for which the Ferranti process was not really suitable. There was nothing wrong with either process or design, they simply didn’t mesh on two of the chip’s functions.

Acorn ran into similar bother when it was designing a monumental ULA for the Electron.

“The layout of the gate array was done manually by draughtsmen putting tape onto plastic film to draw all the tracks for the chip itself, using a scalpel to cut the tape,” remembers Mark-Eric Jones. “In the first chip we had, the outputs were completely non-functional. It turned out it was because someone had forgotten to connect the IO pads around the side to the logic in the core.”

In those early days of gate arrays, there were no electronic design automation tools or digital design simulations to help chip designers, at least not in the UK. Debugging the ULA was an entirely manual process.

“I was catching the shuttle up to Manchester airport so many times, one of the taxi drivers there recognised me,” says Mej.

Fixing the issues Amstrad’s team had uncovered would have involved either redesigning part of the ULA – far too time consuming – or modifying the motherboard with the addition of a lot of extra components to compensate for the signal deficiency, which was too costly. Sugar’s solution, reached while the engineers pondered which of these two options to pick, was to write-off the fee paid to Ferranti and to get an alternative supplier on the case. He figured that losing that money was as nothing to the loss of face and sales that any delay in the computer’s availability would cause.

Numbered prototype

Ambit and MEJ switched from Ferranti’s bipolar process to LSI Logic’s CMOS process for their gate array and after no small job adapting the design to the alternative process, got it working. And then Alan Sugar fell out with LSI which forced a second switch, to Italy’s SGS Microelettronica. Fortunately, SGS was second-sourcing LSI’s process so the change was not an onerous one, but Mej had to spend a couple of weeks in Milan making adjustments. Back home, the move from Ferranti’s ULA to LSI’s gate array had already resulted in a change being made to the PCB, which went from version MC0001A to issue MC0002D.

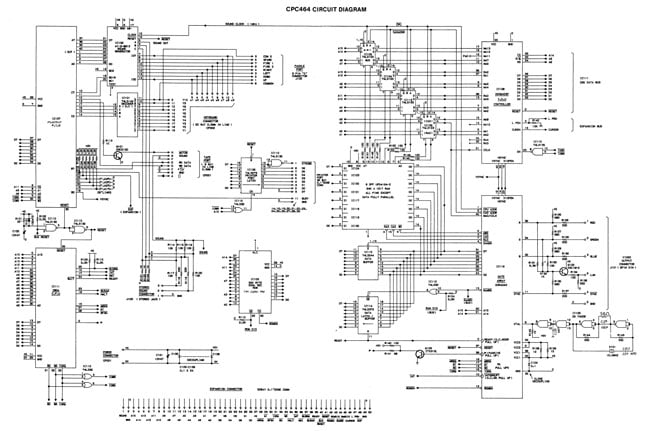

The ULA was home to such features as the 464’s video generator, timing logic - allowing the display controller access to the memory between CPU cycles - the ROM/RAM memory switching, interrupt generation, and the colour palette generator. This latter component output through three pins, for red, green and blue signals respectively. With three possible levels on each - high, low and floating between the two - the 464 was able to deliver its 27 colours.

Alongside the QL

At the CPC 464’s launch in April 1984, Alan Sugar was able to state clearly that all work on the machine had been completed and that its was already being manufactured. He might had said all that anyway, but he was almost certainly encouraged to do so by the highly public delays that Sinclair Research’s latest micro, the QL, was then experiencing post its January launch.

At this stage, Sinclair hadn’t even shipped product and had missed not one but two stated deadlines to do so. When the first QLs began to appear, and no more than a hundred at that, they were found to be buggy and unreliable.

Not so the CPC 464, which, as Sugar had promised, went on sale on 21 June 1984 when a thousand machines were made available to the public by one of Amstrad’s four retail partners, Rumbelows. The quid pro quo for this temporary exclusive – don’t forget, Dixons, Boots and Comet had ordered machines too – was free advertising paid for by the chain. Some 18 software titles were on sale too, from the likes of Gem, Romik, Mikrogen, Bourne, Softspot, Temptation and Britannia.

To be fair to the QL, the Amstrad was using old, established technology - the ageing Z80A processor, clocked to 4MHz; the General Instruments AY-3-8912 three-channel, six-octave sound chip running at 1MHz; a 1MHz Hitachi HD6845 CRT display controller; and an Intel 8255 Programmable Peripheral Interface (PPI) chip. Unlike the silicon in the Sinclair, none of these parts were particularly new. It had one ULA – technically not a ULA since it wasn’t in the end made by Ferranti; it was by now simply a "gate array" – whereas the QL had two, providing much of the Sinclair machine’s functionality.

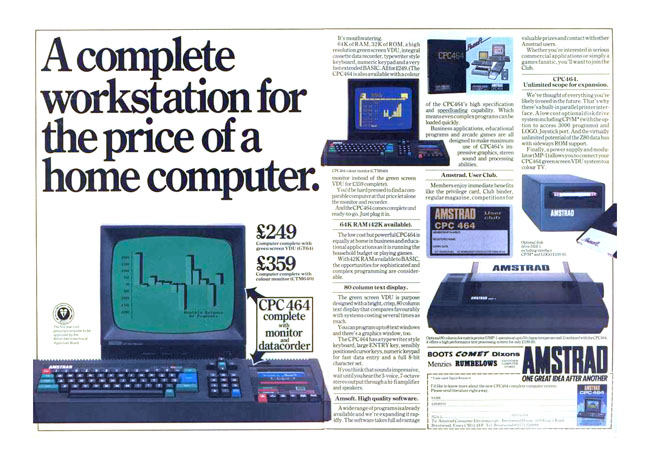

Alan Sugar said that Amstrad would ship versions of the 464 bundled with either a monochrome screen – green, because Sugar thought it would look more techie – or a colour monitor. The two packages would retail for £239 and £349, respectively, though the colour machine was briefly advertised at £359.

Both machines would feature the long-planned integrated tape recorder, 64KB of RAM and 32KB of ROM for Locomotive’s Basic. The monitor would connect to a Din port on the back of the CPC, which was also home to two edge connectors, one for the parallel printer port, the other for a floppy disk controller. There was a 3.5mm stereo audio output socket, and a d-sub joystick port too.

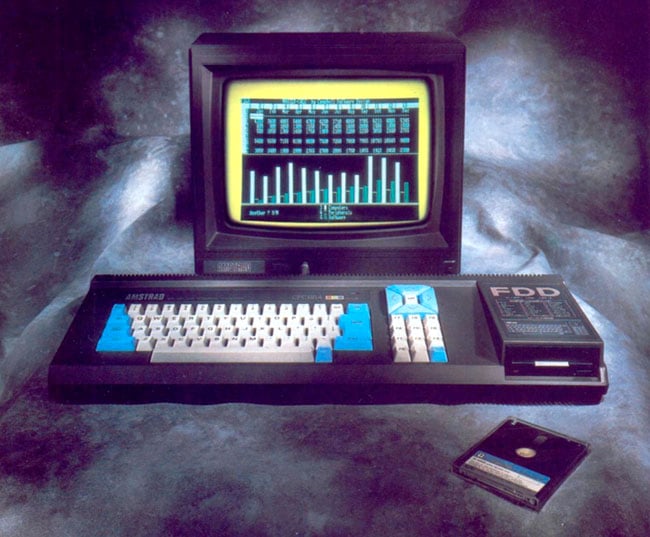

Sugar announced he would offer a 3-inch disk drive and adaptor, all for £199 and bundled Digital Research’s CP/M 2.2, by then the fast fading standard business micro OS. The games demo’d at the launch were loaded in off a floppy drive hooked up to the back of the demonstration 464.

According to Roland Perry, the decision to use the 3-inch disks had been made long before the launch, after the company evaluated all current floppy formats - 5.25-inch, 3.25-inch, 2-inch and even Sinclair’s Microdrive. That was not considered a runner, and the larger floppy wasn’t right either. The 2-inch format, from Fuji, might have made the cut but for the fact that, unlike the 3-inch drive, it wasn’t connector-compatible with the 5.25-inch floppy drives in the PCs being used for CPC software development.

It wouldn’t be until April 1985 that the 3-inch floppy drive was integrated into the computer itself. The upgraded model was launched as the CPC 664. One problem: there wasn’t enough juice coming through the 464’s 5V DC input routed via the monitor to power the floppy drive. The 664 got around this by incorporating a second, 12V power feed, also via the monitor, which was used to power the floppy drive directly.

Naturally, this required a revised motherboard - the changes saw the joystick and sound ports moved round to the left side of the computer, the addition of a DIN port to allow a standalone cassette recorder to be hooked up to the machine, and the placement of a second edge connector, for generic expansion.

Not that Amstrad needed to worry about the delay - the tape-equipped 464 was, in the summer of 1984, garnering rave reviews and pulling in the punters. “I think the Amstrad will give a lot of sleepless nights to Sinclair, Acorn and Commodore, and nightmares to Memotech and Enterprise/Elan,” wrote Andy Pennell in Popular Computing Weekly, neatly summarising the consensus view. “I think it could turn out to be what the QL could, and should, have been: a terrific home micro with an awful lot of potential as a business machine. Those, myself included, who said that QL was going to be the micro of the year could prove to be rather short-sighted.”

In the Autumn of 1984, Amstrad released the DDI-1 disk interface and FD-1 3-inch floppy drive add-on for the 464. The Interface’s ribbon cable had two connectors to allow two FD-1s to be hooked up as A: and B: Amstrad bundled CP/M 2.2 and the Logo language with it. Again, Locomotive supplied the code: a simple disk operating system that was patched onto the firmware when the drive was connected and the 464 booted up.

Floppy disk generation

This software was built into 1985’s CPC 664 too, and the new machine would also feature an updated ROM containing Locomotive Basic 1.1, which also fixed a handful of bugs, including a duff DEC$ keyword that had been broken by some over-zealous "byte hunting" as the Locomotive team tried to cram the 464’s firmware into the two 16KB ROM chips. The new micro was priced at £339 for the mono monitor bundle, £449 for the package with the colour screen. It was codenamed "Idiot", short for "Includes Disk Instead Of Tape".

There were some cosmetic changes made too, most obviously the casing colour scheme and the inflation of the cursor keys – on both the 464 and the 664 wrapped around a central, Copy key – into big, MSX-style keys.

The 664 should have been able to run any program written for the 464, but some machine code apps broke when run on the new machine. There developers found out then why Amstrad had requested they make use of its firmware routines through a published table of entry points dropped into Ram when the machine started up. This approached allowed Locomotive to juggle the ROM routines without breaking compatibility with properly written applications and games. Code that bypassed the RAM jump table couldn’t take into account changes made to the ROM by Locomotive. But many of these broken apps were soon updated

The arrival of the 664 prompted some journalists to assume the year-old 464 would now become cheaper. Alan Sugar disabused them of that idea straight away. “I can’t see any reason why the price should change,” he said at the 664’s launch. “Any reduction we may make would be due to reduction in component prices - not through compromising our market.”

Influenced by MSX? Amstrad’s CPC 664

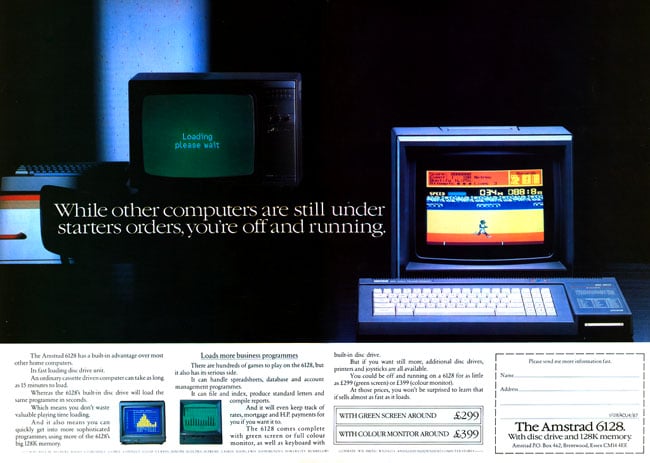

Nor would he supply the 664’s Mk.2 ROMs to 464 owners, or offer any upgrade path from the older machine. Even if he had, users would have been better off waiting a while. Two months later, in June 1984, Amstrad unwrapped a 128KB CPC at the Summer Consumer Electronics Show (CES) in Chicago. News reports from the time are mixed, but it seems that Amstrad said the CPC 6128 was initially destined only for the American market, though it might come to Britain early the following year.

According to Roland Perry, it had been designed at the behest of Amstrad’s US sales partners, who wanted a more capacious machine and one that, after the 464 flopped over there, would look a little more business-like.

Of course, with the cat out of the bag, British resellers began to demand the 128KB model too, and a month after the 6128’s US appearance rumours were flying that the 6128 would debut here early in September, most likely at the Personal Computer World Show. Which is what exactly what happened.

To the annoyance of 664 buyers, the new machine was not only better - updated software and more of it; the extra Ram - but it was cheaper: £229 for the mono bundle, £399 for the colour one. It was a slimmer unit, too, with the Qwerty, cursor and numeric key clusters brought together into a single array. The whole thing look considerably more business like. Meanwhile, gamers after a bargain could now pick up the still extant 464 for £199 or the colour version for £299. With the arrival of the 6128, the 464 finally dropped to the price Alan Sugar had originally wanted to sell it for: just under £200.

“The 6128 is the most attractive new 8-bit micro so far this year. The only people who may complain will be those who have just brought an Amstrad 664,” wrote Jeff Naylor in Popular Computing Weekly. Indeed, it’s telling that Lord Sugar, in his autobiography, skips over the 664 entirely and says the 6128 was the follow-up to the 464. Perhaps all that firing has affected his memory...

Amstrad could get away with it. It was by now better known as a maker of good microcomputers than as a seller of budget hi-fi. In the year to the end of June 1984, into which the then-new 464 had just fallen, computer products accounted for four per cent of Amstrad’s sales. Twelve months on, that proportion had risen to 66 per cent, pushing sale up 60 per cent to £136.1 million of which £20.1 million was profit, itself up 122 per cent.

British home computing: the next generation

And this over a period that had seen Acorn slip off the edge, only to be grabbed and pulled back by Italy’s Olivetti, and for cash crises to send Sinclair Research cap in hand to Robert Maxwell.

Sinclair was spared being forced to sell a large stake to the tycoon for £12m by a big order from Dixons placed with the specific intention of keeping the Spectrum maker afloat. But the writing was on the wall. In February 1986, Amstrad lauded another leap in profits. Sinclair Research plunged even further into the red. It crashed, and Alan Sugar was able to by the Sinclair brand and intellectual property for £5m.

If the pioneers of the 1980s home computer boom were gone or being kept alive with others’ money, Amstrad was on a roll. The CPC series continued to sell nicely, but the September 1985 launch of the PCW 8256 word processor - just a Z80A-based all-in-one with 256KB of RAM, an integrated 3-inch floppy and a bundled printer - sent the company surging forward. Amstrad went on to ship eight million PCW-series machines, more than double the 3m CPCs it sold.

A month after the Sinclair purchase, Amstrad announced its first PC and though this machine suffered several setbacks, the line won good reviews and sales aplenty. In time, Amstrad would ship 12 million of them and become Europe’s leading supplier of PCs.

During this time the CPC line continued to be sold but the shifting nature of the market ensure it wasn’t updated in any way until 1990 when, on the back of an attempt to create a games console to compete with Nintendo and Sega, Amstrad re-styled the line with new, Amiga-like cases. The sound and graphics were souped up, the "CPC" prefix dropped. Like the GX4000 console, the 464 Plus and the 6128 Plus were commercial flops: just too out of date for current gamers’ demands. They were soon dropped from the Amstrad line-up.

Alan Sugar was knighted in 2000 and ennobled in 2009. Throughout the 1990s and the first half of the following decade he was chairman of soccer club Tottenham Hotspur, though he continued to run Amstrad during this time too. The company shifted away from computers, though it acquired computer maker Viglen, and into communications devices and, later, set-top boxes.

In 2007, Sugar sold Amstrad to BSkyB for £125m; Amstrad had by now become Sky’s hardware manufacturer. Sugar himself resigned the chairmanship the following year. He remains chairman of a number of family owned businesses. He has, of course, made regular appearances in TV shows like The Apprentice since 2005.

Roland Perry left Amstrad in 1990. Later that decade he worked for internet service provider UK Online, a move which shifted his focus to the internet and related issues, particularly in the realm of public policy and legislation: since then has been a lobbyist for the Linx, the London Internet Exchange, and handled public affairs for the Internet Crime Forum, the Réseaux IP Européens Network Coordination Centre (RIPE NCC) and now The Internet Policy Agency.

Bill Poel left Amstrad in 1985, became a columnist in the weekly technology trade paper, MicroScope - where this writer had the pleasure of sub-editing his copy - and went on to work in a number of ventures, including Quarterdeck, Enformatica, USP Networks and IncentTV. He’s now UK envangelist for interactive video toolmaker TouchCast.

Marc-Eric Jones continued to develop Amstrad hardware at MEJ, including all of Amstrad’s PCWs, PCs and its portable computers. Having developed a number of EDA tools to help in the design of ASICs and other custom silion during the Amstrad period, MEJ’s business later shifted toward the development and licensing of those tools to chip companies, which prompted a change of name, to 3Soft, and new location: California.

In 1996, Mentor Graphics bought 3Soft, and for the next three years Mej established and ran its IP licensing business. He later steered fabless memory technology company MoSys’ licensing operation. In 2004, he was poached to run Z-RAM memory creator Innovative Silicon. These days he runs Leman Micro Devices, which is working on advanced smartphone sensor technology.

Richard Clayton and Chris Hall continue to work together, though they now run Highwayman Associates, which is now developing technology for software-defined networks (SDN). Locomotive and Amstrad parted ways after the development of the Amstrad PC. In the early 1990s, Locomotive developed Turnpike, an internet access utility, for British ISP Demon; Demon liked it so much it bought the company.

Staying beyond their earn-out periods, the two men quit the company in 2000 and 2003, respectively. Demon was acquired by Sottish Telecom in 1998 and became known as Thus. After leaving Thus, Clayton returned to Cambridge university to pursue his PhD and is now an academic there with a special interest in e-crime. Chris Hall has since taken senior positions at Communications Innovation Institute and cloud services company Interoute. ®

The author would like to thank Roland Perry, Richard Clayton, Mark-Eric Jones, Bob Watkins and Simon Rockman for their invaluable help in the research of this article.