Original URL: https://www.theregister.com/2013/01/10/firefly_structures_for_leds/

Fireflies donate gut feelings to LED research

Belly, belly, burning bright

Posted in Science, 10th January 2013 02:28 GMT

Structures that help fireflies produce bright light from their abdominal lanterns have been mimicked in the lab to increase the efficiency of LEDs.

In their Optical Express article, the researchers explain that the jagged structures they found on the Photuris Lampyridae firefly enhanced the glow of their lanterns. By creating an overlayer that mimicked these structures, the boffins say they extracted 55 percent more light from LEDs in the lab.

As the French/Belgian/Canadian authors note, the overlayer “can be tailored to an existing diode design rather than requiring a complete redesign of the diode geometry”, which would greatly simplify real-world implementation of the technique.

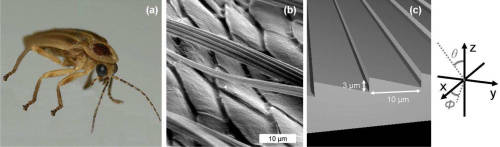

The structure of the abdomen resembles a factory roof made up of chitinous scales, something easily replicated with a photoresistant material deposited on top of a GaN (gallium nitride) LED.

From left, the firefly; the natural scale structure; and the artificial structure.

Source: Optics Express

Compared to a planar surface, the researchers explain, the jagged structure improves light extraction by minimizing internal reflections – a problem common both to the firefly and to LED design.

University of Namur doctoral student Annick Bay told UPI: “What's nice about our technique is that it's an easy process and we don't have to create new LEDs. With a few more steps we can coat and laser pattern an existing LED.”

As noted in the journal article:

“The fabrication technique applied in order to obtain corrugated overlayer has the advantages of simplicity and scalability: a homogeneous layer of photosensitive resist is first deposited by spin coating on the whole surface of the wafer and left to harden; then, on each diode, appropriate radiation penetrates the photoresist to a depth proportional to intensity, the illuminated region being then easily removed. This technique allows for the production of any profile on a precise area of a large surface.” ®