Original URL: https://www.theregister.com/2012/12/13/flying_truss_update/

LOHAN fabricates full-fat fantastical flying truss

Vulture 2 launch platform hewn from carbon-fibre rods

Posted in Science, 13th December 2012 09:02 GMT

The Low Orbit Helium Assisted Navigator (LOHAN) team has bounced back from the recent loss of our heroic playmonaut and the Special Project Electronic Altitude Release System (SPEARS) control board, and is busy advancing our audacious spaceplane project on various fronts.

While we look to recruit a replacement for our diminutive pilot, we've already put together another SPEARS board with a view to a second test flight - preferably in the centre of some enormous landmass where there is no chance of an unexpected close encounter with the sea.

While we look to recruit a replacement for our diminutive pilot, we've already put together another SPEARS board with a view to a second test flight - preferably in the centre of some enormous landmass where there is no chance of an unexpected close encounter with the sea.

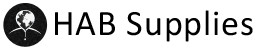

Our intrepid playmonaut perished while riding a one-quarter scale model of the fantastical flying truss - the structure which will carry the Vulture 2 spaceplane aloft. Here's Neil Barnes just before the launch, bearing both the SPEARS payload box and truss:

We'd hoped to grab some footage of just how the truss performed at altitude, and we probably did, although since the GoPro HD HERO2 camera is now lying at full fathom five beneath the English Channel, recovering the SD card could prove a tad challenging.

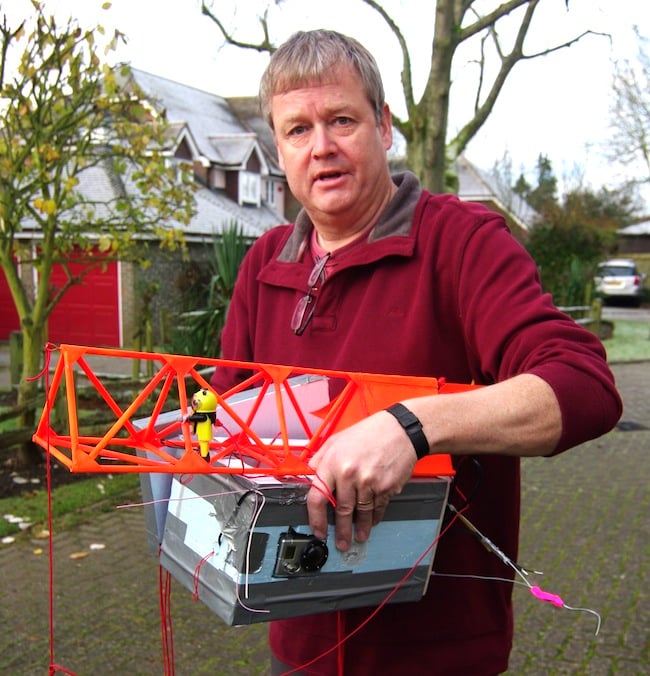

Nonetheless, we're determined to press on with this vital mission component, and are delighted to report we now have the full-scale truss partially assembled from 12.5mm carbon fibre tubes and off-the-shelf connectors:

The result of gluing all the bits together with Scotch-Weld 2216 Epoxy ("certified for aircraft and aerospace applications" and "excellent for cryogenic bonding applications", we're assured), is a 2-metre long, super-strong, super-light structure more than capable of supporting the Vulture 2's titanium launch rod.

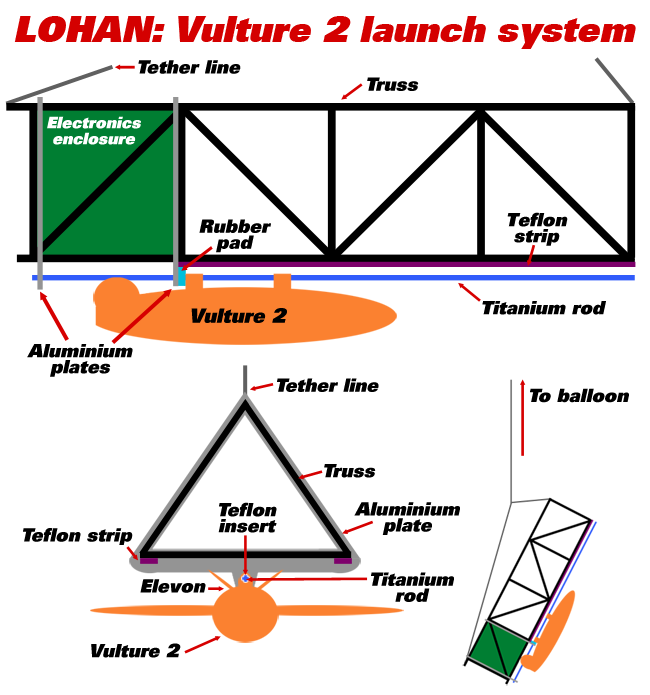

Here's an updated graphic of how the whole set-up works:

You'll notice in the above snap that we've left the electronics enclosure bit of the truss open for now. That's because we not quite sure of the dimensions of the aluminium plates which will hold the titanium rod to the truss.

The distance between the rod and the truss's underside depends on the final size of the spaceplane. The plan is to allow the Vulture 2 to pivot on the titanium rod using two Teflon inserts in the top of the fuselage. This slight motion will prevent the inserts icing to the rod during the ascent to launch altitude, and here's one of the inserts during freezing tests earlier this year, which proved the idea works:

Since the Vulture 2 can rock on the rod, there's the potential problem of the wings hitting the longitudinal truss members. The solution is to run a Teflon strip with a soft foam backing along the length of these members, and to minimise the distance between wing surface and strip.

When the rocket motor fires, the strips will acts as "guides" as the aircraft travels along the titanium rod, and prevent spinning. Icing of the Telflon strips will be mitigated by an application of the same Molykote 33 low temperature grease we'll use to lubricate the titanium rod.

Once we've got the whole truss and rod assembled - and we're still mulling whether the rig needs a tail - we'll be able to build the electronics enclosure inside the bottom end. It'll be a styrofoam box containing the SPEARS board and motor igniter batteries, motor heater battery, cameras and any other bits and pieces which need protection from the cold.

So, it's onwards and upwards for LOHAN, as we prepare the final move from our first fantastical flying truss tests back in March...

...to a full-blown spaceplane launch platform. ®

Further LOHAN resources:

- New to LOHAN? Try this mission summary for enlightenment.

- You can find full LOHAN coverage right here.

- Join the expert LOHAN debate down at Reg forums.

- All the LOHAN and Paper Aircraft Released Into Space (PARIS) vids live on YouTube.

- For our SPB photo archive, proceed directly to Flickr.

- We sometimes indulge in light consensual tweeting, as you can see here.