Original URL: https://www.theregister.com/2012/11/23/lohan_heater_update/

Warming up the thruster that will ram LOHAN to glorious heights

Project team prepares to shove pocket rocket in toaster

Posted in Science, 23rd November 2012 13:22 GMT

Our audacious Low Orbit Helium Assisted Navigator (LOHAN) spaceplane project continues to advance on multiple fronts, and while Neil Barnes and Anthony Stirk put together the Special Project Electronic Altitude Release System (SPEARS) control board, we've been doing some more work on the Vulture 2 rocket motor heater set-up.

To summarise, we know a solid rocket motor will fire at altitude, but the effect of very low temperature on the thruster's ammonium perchlorate composite propellant (APCP) is unknown.

To summarise, we know a solid rocket motor will fire at altitude, but the effect of very low temperature on the thruster's ammonium perchlorate composite propellant (APCP) is unknown.

To launch a pre-emptive strike on this potential problem, we decided to heat the motor on the ascent phase of the mission, and got our hands on a space-grade Polyimide Thermofoil flexible heater.

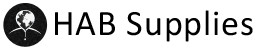

The heater's effective area is 300.257 cm2, and its resistance is 64Ω. At 12V it draws 0.1875A and pumps out 2.24W, which translates to a watt density of 0.0078W/cm2. We hooked it up to a 1300mAh Lithium Polymer (LiPo) battery (11.1V nominal)...

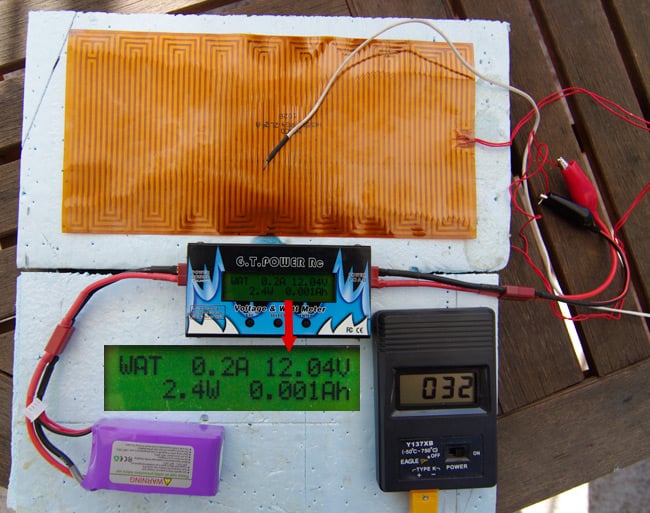

...and the first results were encouraging. Here's how the LOHAN toaster performed when sandwiched between two sheets of styrofoam:

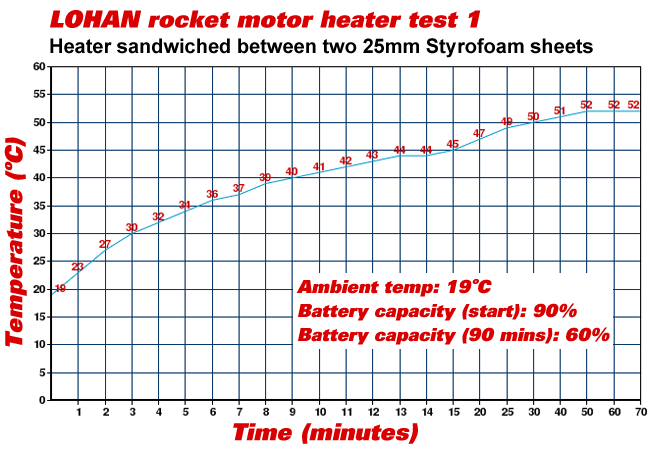

Two is one, one is none

In fact, we have two heaters - just in case one succumbs to the rigours of testing - so we plugged in the second to check it was in good health. Here's the result, again when sandwiched between two styrofoam sheets:

That's all well and good, but when the heater makes its way to the stratosphere, it'll be wrapped round the aluminium motor casing, and sealed on with heatshrink. A layer of space blanket between heater and plastic will provide some insulation.

That's the plan, anyway, so we need to have some idea of whether the thruster will stay toasty without extra insulation.

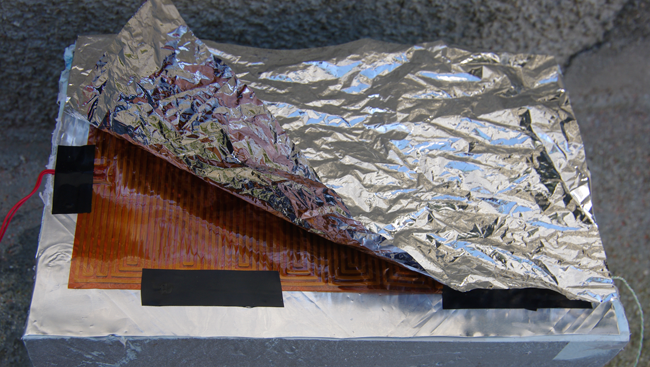

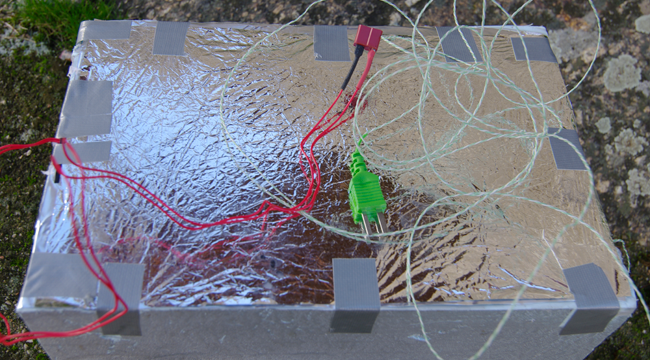

Accordingly, we glued an aluminium sheet on top of some styrofoam, taped the heater on top...

...and then stretched some space blanket over the heater, having first stuck in a K-type thermocouple to monitor the temperature:

In the best tradition of garden-shed bodging, we then slapped on a rubber sheet to simulate the heatshrink. It's actually a piece of shower mat, complete with designer suction pad motif:

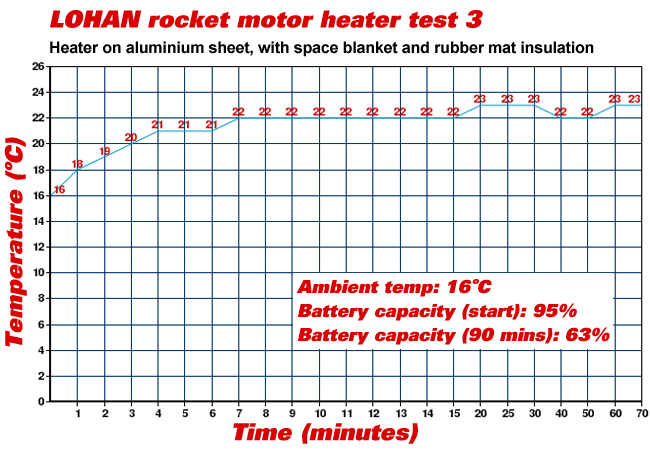

Unsurprisingly, without the benefit of a styrofoam sandwich, and with the aluminium sheet slurping up the output, we won't be frying eggs on this test set-up:

This may look like a very modest temperature rise, but there's one thing we have to bear in mind: the lack of atmosphere at altitude may prevent heat radiating away from the motor.

In fact, this effect is exactly why you don't have to heat electronics on High Altitude Ballooning (HAB) flights. On the contrary, you have to be careful they don't melt down.

So, we know what you're thinking - and we agree that the only way to find out is to send the test rig heavenwards with a temperature logger and see what happens. Watch this space... ®

Further LOHAN resources:

- New to LOHAN? Try this mission summary for enlightenment.

- You can find full LOHAN coverage right here.

- Join the expert LOHAN debate down at Reg forums.

- All the LOHAN and Paper Aircraft Released Into Space (PARIS) vids live on YouTube.

- For our SPB photo archive, proceed directly to Flickr.

- We sometimes indulge in light consensual tweeting, as you can see here.