Original URL: https://www.theregister.com/2010/09/15/qinetiq_result/

PARIS emerges triumphant from hypobaric chamber

Vulture 1's Mk 2 release mechanism cleared for take-off

Posted in Science, 15th September 2010 14:42 GMT

We know you lot haven't been able to eat or sleep pending the outcome of Monday's test of our Paper Aircraft Released Into Space (PARIS) Mk 2 release mechanism, so here's the news: it works.

For PARIS newbies, we should explain that said mechanism is the pressure-operated device which will release the Vulture 1 aircraft. It's based on the simple fact that air in an enclosed space expands as the external pressure drops, so you can, in theory, translate that into mechanical motion which in turn can be exploited to drop your plane at the desired height.

For PARIS newbies, we should explain that said mechanism is the pressure-operated device which will release the Vulture 1 aircraft. It's based on the simple fact that air in an enclosed space expands as the external pressure drops, so you can, in theory, translate that into mechanical motion which in turn can be exploited to drop your plane at the desired height.

We previously tested a Mk 1 mechanism - a big glass syringe - down at QinetiQ's hypobaric chamber facility in Farnborough, and there are details of the less-than satisfactory outcome here.

However, QinetiQ's Chas Taylor and Tim D'Oyly were able to suggest an alternative set-up using the same principle. Enjoy the concept graphic:

Suitably inspired, we got stuck into putting this fine piece of British engineering together, and before reading on you're advised to get the background construction details here and more on our final preparations for the QinetiQ test right here.

In summary, though, this is what the beast looks like fully assembled...

...and it was just a matter of putting it in this...

...to see if it would actually deliver or we'd all have to seek alternative employment flipping burgers.

So, Monday morning bright and early we rolled up to QinetiQ for the second time, and quickly set about preparing the mechanism for its date with the hypobaric chamber:

Here are a couple of crucial ingredients you won't have seen before: an expensive low-temperature grease, good to -73°C, according to the manufacturer, plus some 40 grit aluminium oxide:

What, you're wondering, is the aluminium oxide for? Well, Tim D'Oyly shared the concerns of several Reg commenters about filling the oxygen tube with liquid, lest it freeze.

He suggested using a fine sand as the ballast instead, so we thought we'd give that a shot before resorting to a mixture of water and antifreeze. This revised plan enabled us to dispense with the fill valve, and simply compress the oxygen tube fully, stick in the required amount of grit and then seal the open end with a plain rubber bung.

He suggested using a fine sand as the ballast instead, so we thought we'd give that a shot before resorting to a mixture of water and antifreeze. This revised plan enabled us to dispense with the fill valve, and simply compress the oxygen tube fully, stick in the required amount of grit and then seal the open end with a plain rubber bung.

What you're then left with is a fully compressed tube of about 70cc, of which around 55cc is is filled with grit. The remaining air is what, on paper, drives the release mechanism "release rod" which drops the Vulture 1.

Of course, you want to keep friction in the system to a minimum, so it fell to our very own John Oates to grease the bits and pieces, as you can see.

After half an hour of fiddling, we stuck the whole assembly in the hypobaric chamber. In the spirit of garden shed boffinry, it's supporting a test weight of 500 grammes of alumimium oxide grit in a plastic milk carton:

You'll note a few extra bits and pieces sharing the table. At top centre, you can see three chunks of test foam: polystyrene, styrofoam and coarse packing foam.

They're in there to see if, as several of you predicted, they will expand at altitude. We glued a strip of paper round each to have physical evidence of any bloating. Styrofoam is an essential mission material, since it houses the Vulture 1 GPS/APRS unit, and our main payload box is entirely made of the stuff.

Below the foam are two lengths of paper straw, each sealed at boths ends with glue, but one enjoying the benefit of a tiny vent hole in its length, made with a needle.

Finally, we've got our Mk 1 mechanism. Suspicions were that it didn't work because air was seeping between the surface of the ground glass plunger and the inside of the syringe. To find out, we slapped some of the low-temperature grease on the plunger.

And now the big moment. Did the Mk 2 mechanism work? Did the greased Mk 1 shake its bootie? Did the styrofoam bloat like Vanessa Feltz at an all-you-can-eat buffet? Did the unvented straw go bang?

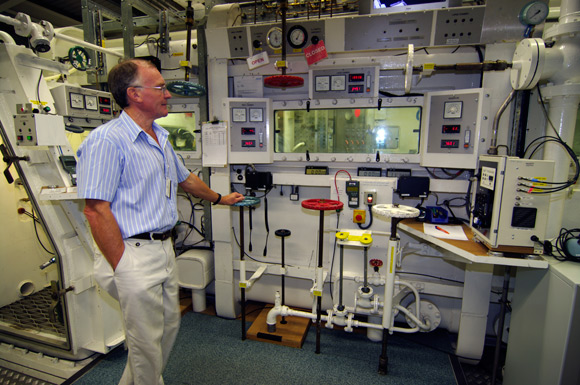

Only one man could answer these questions: Chas Taylor at the controls...

And the answers to these questions are: yes, no, no and no, respectively.

First up, try the Mk 2 release mechanism, operating at an ascent rate of 1,000 feet a minute:

Lovely. Obviously, we've speeded up the vid for your viewing pleasure, and you'll note that the plunger rod extended in small "jerks" as the pressure in the oxygen tube built to the point where it overcame the friction in the system, and pushed the release rod out a little bit.

The first drop came at 33,000 ft, so we took the whole thing apart and compressed the oxygen tube further to remove some surplus air. The second drop was at 48,500 ft, which more than satisfied us given that it's nigh on impossible to accurately calibrate the mechanism.

One thing is certain, though: the Mk 2 will definitely release the Vulture 1, and whatever the final altitude, it's going to be a bloody long way up.

A final note on the Mk 2: Yes, we know the plunger rod droops as it comes out of the PVC tube. We're putting together a simple guide system to keep it on the straight and narrow.

The results from the other stuff in the chamber proved interesting:

- Neither the styrofoam nor the polystyrene expanded at all, but the coarse packing foam surprisingly did. Presumably air bleeds out from the first two, but the large bubbles of air in the last have nowhere to go.

- Both straws were unaffected by the change in altitude. Either the air escaped through the surface of the fully-sealed straw, or it's strong enough to take the pressure.

- The Mk 1 didn't work again, even with the grease.

And finally, we'd like to note that the Kodak Zx1 video camera - destined for the main payload box - was in the chamber, and grabbed some of the footage in the above vid. It shut itself down after 30 minutes, and then one minute into a second run, so we'll have to see if the pressure drop has done it some damage.

In the meantime, it's beers all round here at PARIS headquarters, and hearty applause for Tim D'Oyly, Chas Taylor and QinetiQ, without whose help PARIS would currently be going nowhere.

As it is, we're ready to move into the final straight, and prepare for launch... ®

Additional PARIS resources

- Our dedicated PARIS section, with all previous updates, is right here.

- New to PARIS? We have a basic mission summary here (pdf).

- Our Flickr page, with all previous photos.

- Check out our YouTube channel - currently featuring a few kit tests.