This article is more than 1 year old

Back to the nano-mechanical future

Nano-cantilever memory solving flash conundrum

Edinburgh researchers and others have devised a way to use nano-cantilevers to charge carbon nanotube transistors with binary values faster and more power-efficiently than NAND cells get charged. Once again the scientists raise the possibility of their invention replacing flash, as many have done before.

As reported in Nature Communications, the problem the researchers at the University of Edinburgh, Konkuk University and Seoul National University, Korea, were trying to solve was how to use carbon nanotubes as a memory storage device, and have it out-perform flash memory. Flash, they say, takes about 10 microseconds to write and 10 milliseconds, a thousand times longer, to be erased.

Carbon nanotube-based alternatives have been non-starters because they have slow operational speeds and short retention times.

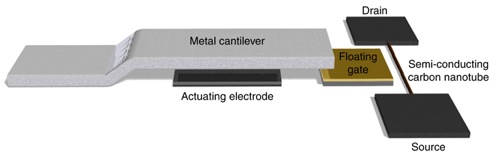

Cantilever, floating gate and carbon nanotube device (Nature Communications)

They settled on the idea of using the electro-mechanical motion of a cantilever to deliver faster charging of a floating-gate electrode, which controls the charge transport through a carbon nanotube field-effect transistor (CNT). The researchers used radio frequency microelectromechanical system switches (RF MEMS) because they switch at high-speed and have low power consumption plus other advantages. Previously other researchers have devised 3-terminal relays, crossed nanotube arrays and vertical nanoscale memory cells but these approaches have operational challenges and reproducing their fabrication is difficult, the Edinburgh, Konkuk and Seoul researchers say.

They built their cantilever-charged CNT device and say: "The experimental results show that the device performance is superior to that of conventional flash memories."

They say a floating gate is used in NAND cells, being placed on metal-oxide-semiconductor field-effect transistor (MOSFET) and electrons tunnel to the floating gate through an insulating dielectric layer. This tunnelling causes a time delay and also limits "the number of useful cycles that can be achieved." The cantilever in their device directly contacts the metallic floating gate:

The cantilever is anchored at one end and it is suspended above the actuating electrode and the floating gate. When a bias voltage is applied to the actuating electrode, the resultant electrostatic force pulls down the cantilever until it contacts the floating gate. The cantilever is composed of Cr/Al/Cr triple layers and the floating gate is made of Au. The Au floating gate is placed on top of an 80-nm-thick Al2O3 layer. In this configuration, the floating gate is charged at the instant of contact.

At the moment of contact, the negative charges in the cantilever charge the floating gate instantaneously. By inducing negative charges on the floating gate, the CNT channel is turned 'ON' with hole-transport. We define this as the 'programmed state' or bit '1'. By turning off the actuating electrode voltage, the cantilever is moved back to the original position and the contact between the cantilever and the floating gate is switched off. The floating gate remains negatively charged, and the CNT channel is maintained in the 'programmed state'. The 'erased state' or bit '0' is obtained by reversing the programming processes.

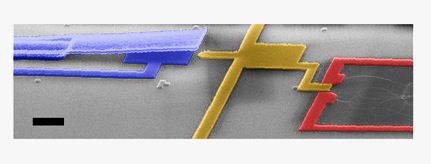

Field-emission scanning electron microscope image of the device. Colour-coded to show the main elements: source/drain (red), floating gate (yellow) and cantilever/actuating electrode (blue). Scale bar, 2 μm (Nature Communications).

The researchers say "a much longer retention time is expected as the floating gate is completely isolated without any electrical connections or significant leakage once the cantilever has been positioned in the up-state.