This article is more than 1 year old

El Reg's plucky Playmonaut eyes suborbital rocket shot

Open source 'Earendel' project aims high on Kickstarter

Those of you who like your rockets liquid-fuelled and your altitudes suborbital might like to have a shufti at "Earendel", which promises to be "the first vehicle capable of reaching space, ie, greater than 100km, with an entirely open source design".

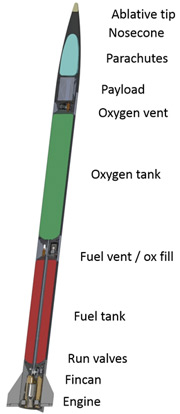

Earendel (left) - named for the Anglo-Saxon morning star - is the brainchild of Lloyd Droppers and Jasmine Cashbaugh, who are banking on "a single stage liquid sounding rocket ... powered by a 200 lb thrust Liquid Oxygen (LOX) / Isopropanol (Rubbing Alcohol)" motor to ultimately lift "a payload equivalent to a standard cubesat (1.33kg)" past the symbolic Kármán line.

Earendel (left) - named for the Anglo-Saxon morning star - is the brainchild of Lloyd Droppers and Jasmine Cashbaugh, who are banking on "a single stage liquid sounding rocket ... powered by a 200 lb thrust Liquid Oxygen (LOX) / Isopropanol (Rubbing Alcohol)" motor to ultimately lift "a payload equivalent to a standard cubesat (1.33kg)" past the symbolic Kármán line.

The plan is to make all the documentation available to the unwashed masses, so they too can join the amateur space race. Some parts will be off the shelf, others printable in 3D, and the design is intended for self-assembly using hand tools.

At Earendel's heart is "a pressure-fed film-cooled* engine", which "runs at 180 psi for relatively low pressure tanks and produces 200 lb thrust". The blurb continues: "The design is a machined concentric tube chamber. The injector is a metal 3D-printed piece with integral inlet and pressure ports.

"It uses a sparse field of unlike doublet impinging jets** and film cooling - effectively boiling alcohol on the chamber wall to keep it cool. The engine is designed for ease of use, simple fabrication, and durability and is expected to achieve a sea level Isp (specific impulse) of 205 sec with a 90 per cent efficiency."

Rocket trajectory is maintained by "servo-actuated fintabs", controlled by a single Arduino Leonardo, which also does all the other mission computing work.

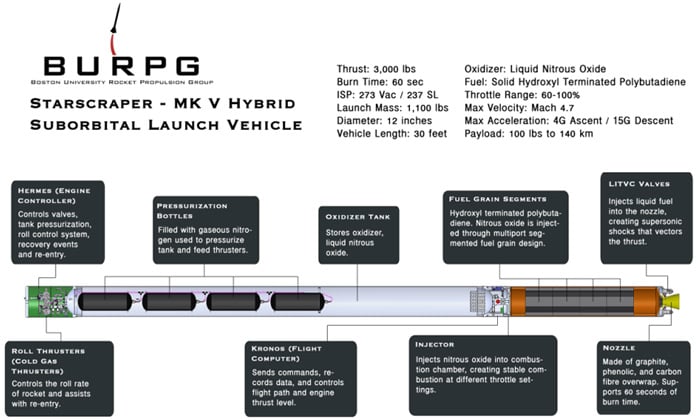

The choice of powerplant is interesting. Another suborbital rocket project - the Boston University Rocket Propulsion Group's Starscraper - recently hit its funding target on Kickstarter, and will head heavenwards using "relatively underdeveloped" hybrid motor technology.

The Starscraper motor uses hydroxyl-terminated polybutadiene (HTPB) fuel and nitrous oxide oxidiser. Space aficionados will know that Virgin Galactic's SpaceShipTwo engine originally ran on the same mix, although the HTPB was subsequently replaced with polyamide plastic fuel.

However, the first amateur rocket to officially hit 100km was the Civilian Space eXploration Team's "GoFast", which in 2004 thundered to an apogee of 115.8km using an ammonium perchlorate-based solid propellant.

Indeed, it's ammonium perchlorate composite propellant (APCP) that will power our own Vulture 2 spaceplane, so we asked Lloyd Droppers why Earendel will pack a liquid-fuelled motor instead of a simple solid-fuel unit.

He told us: "While it is true that solid rockets motors have fewer moving parts and are reliable once fully designed and tested, the design phase is as hard as a liquid engine design. Solid rockets also have high thrust to weight at take-off which requires stronger vehicle structure and a worse vehicle thermal load.

"We are using liquid propellants, but we are simplifying the system as much as possible by removing pumps and regeneratively cooled chambers, two of the hardest parts of the propulsion system. We also chose to use liquid-fuelled engines not just for this mission, but also due to the program's open source nature.

"A solid motor is hard to modify for a new mission but, for a liquid rocket engine, it is easier to modify individual components and have a community that updates and uses the system for their own missions - which is the aim of any open source project."

Well, we wish Earendel the best of British, and it'll be interesting to see how amateur suborbital tech develops during this new race for space. Naturally, our own plucky Playmonaut has decided he wants a piece of the action when the time comes to reach for the heavens...

®

Bootnotes

*For details on film cooling see this substantial document (PDF).

**"The injectors use a dozen elements of impinging fuel and oxidiser jets to inject and mix the propellant in the engine," Droppers explained.